Instructions for use

Aquafighter® - a true revolution in fuel quality management and fuel tank maintenance

- Short & Long-term savings on maintenance and capital equipment

- Demulsifies diesel & biodiesel blends by maintaining water levels below fuel specification in the tank at all times

- Protects fuel tanks from microbial growth, corrosion and other related damages caused by water accumulation

- Non-toxic, safe to handle and safe for the environment

- Stops the domino-effect of water damage degrading both the fuel and fuel system, which ultimately will affect

operational equipment and diesel engines - Facilitates fuel-quality management, preserving your fuel tank condition better than other combined solutions

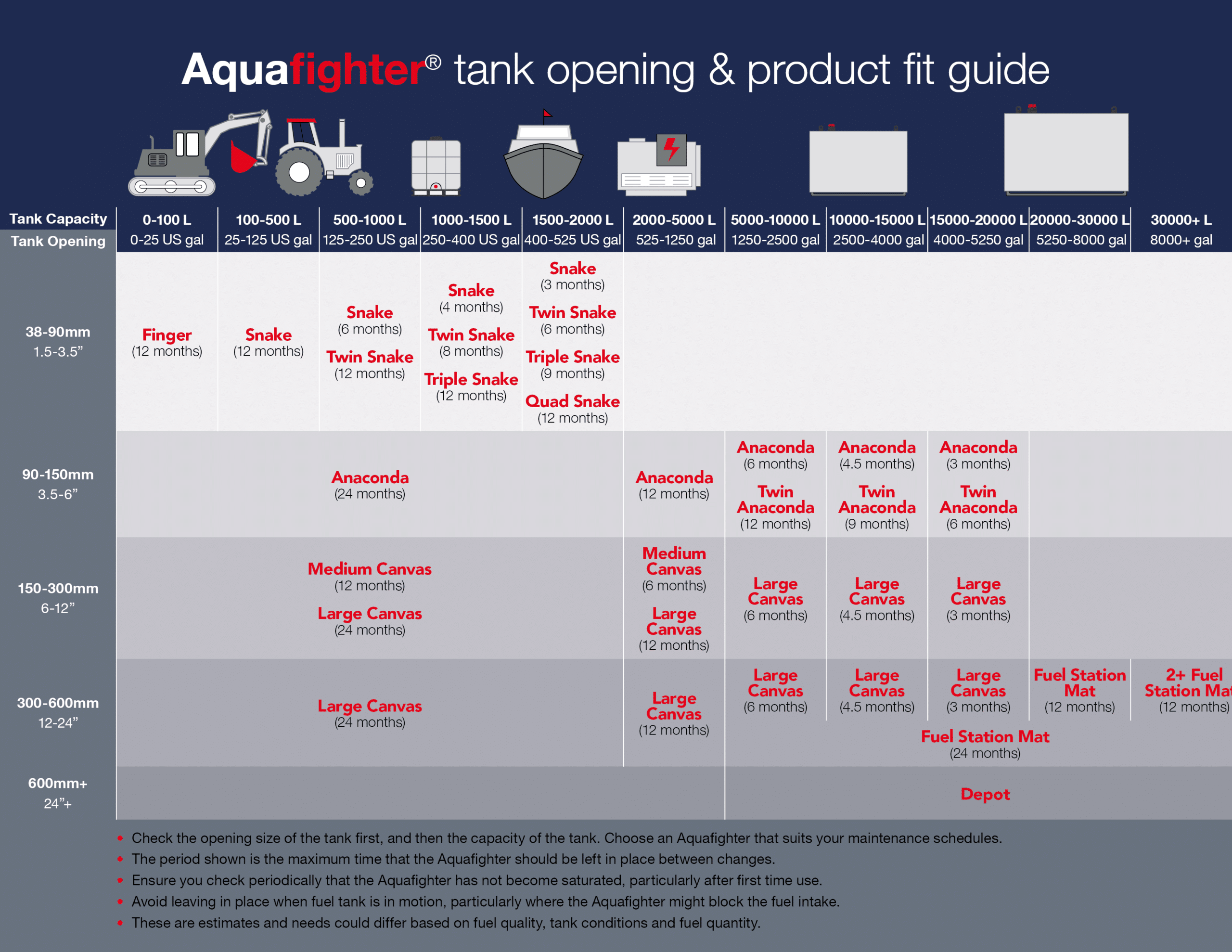

Select the correct size Aquafighter® for your fuel storage tank:

Check the opening size of the tank first, and then the capacity of the tank. Choose an Aquafighter® that suits your maintenance schedules from the table below:

Identify your tank conditions:

Firstly, identify the current state of the fuel and storage tank.

While performing a visual inspection, if the fuel is hazy to a point where you cannot distinguish the inside of the tank, here are some options for you:

- Take a drain or bottom sample from the fuel tank, test each sample for microbial contamination using a FUELSTAT test kit

- Introduce the Aquafighter Dipstick Indicator into the tank to check for free or emulsified water content

Tank is clean and fuel is in good condition with low water content:

- Install Aquafighter following instructions in next steps and maintain water-free conditions

- Check periodically and replace Aquafighter when full or almost full and your tank will not suffer the fate of the next 3 examples

This is the ideal scenario for use of Aquafighter. As always, prevention is better than cure, so look to install Aquafighter from new into clean tanks with clean fuel for long trouble-free service

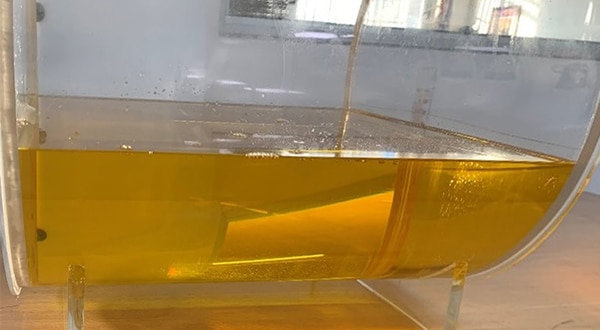

Fuel has significant water content (high ppm):

- Drain free water from the bottom of the tank

- Aquafighter can then be installed to remove emulsified water

- Aquafighter will immediately start demulsifying fuel and should be checked after two days to determine the level of saturation

- When the Aquafighter product (water absorbing powder) fills 50% of its chamber, replace the product with a new one to maintain water-free conditions

Fuel and tank has some water content + sludge and microbial contamination:

- Tank should be emptied and cleaned first to prevent this sludge and microbial growth from clogging filters and getting into machines

Refill with clean fuel - Aquafighter can be installed to remove bound/emulsified water

- Check for levels of microbial contamination in the fuel using FUELSTAT test kit

- It only makes sense to care for your tank so that your fuel will treat your machines well

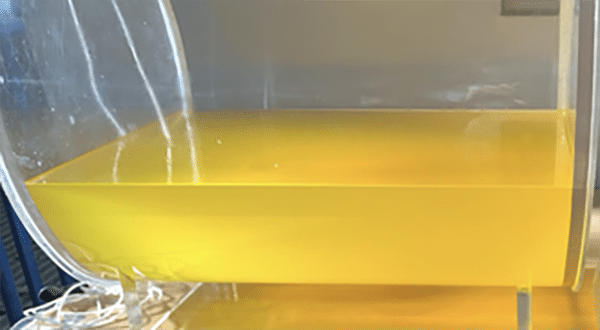

Fuel and tank has significant water content + heavy sludge and microbial content:

- Whether you use Aquafighter or not, if your tank looks like this, you should not put this fuel in anything of value

- Empty and clean this tank thoroughly and visually inspected if possible before re-use

- Refill with clean fuel

- Install Aquafighter and begin a new era of clean tank and clear & bright fuel

- Check for levels of microbial contamination in the fuel using FUELSTAT test kit

Installation:

Prepare:

Carefully remove Aquafighter from the airtight pouch.

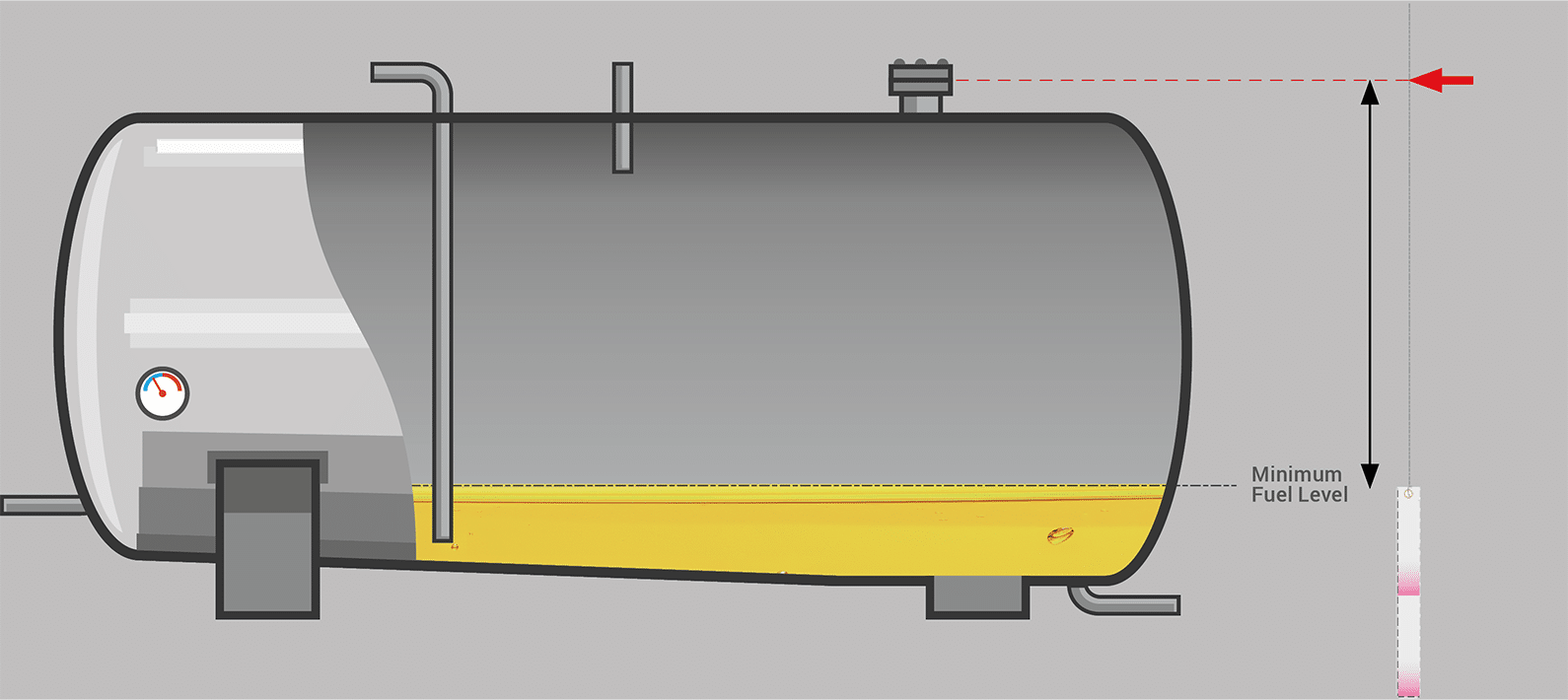

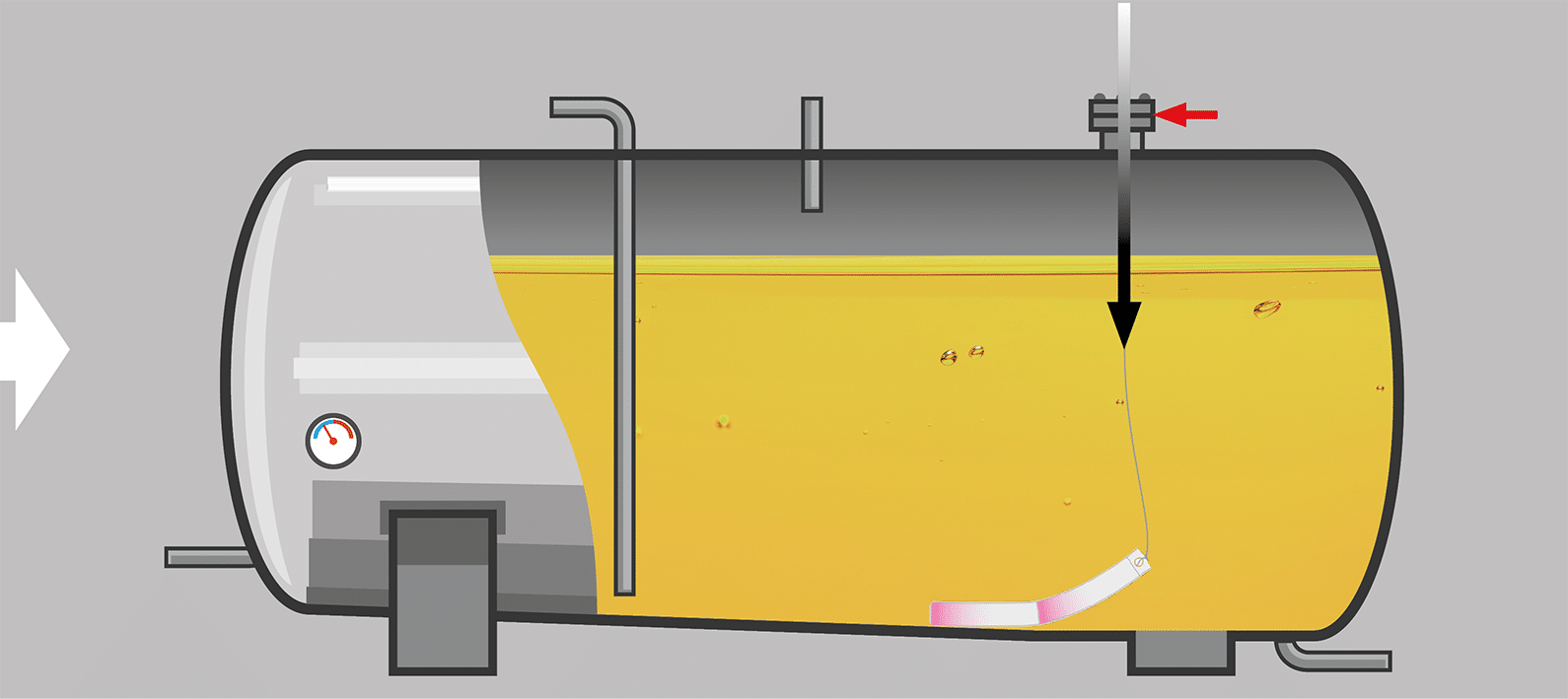

Measure the correct position of the Aquafighter from outside the tank and mark the cord/string length to the tank opening such that the top of the Aquafighter filter will be just below the low fuel level in the tank.

Install:

Lower the Aquafighter into the tank low point location so that the Aquafighter is resting on the bottom being lightly suspended in the tank, using the mark on the cord as reference.

Secure:

Ensure that sufficient length of cord is left outside the tank so that it can be attached, e.g. by making a loop around the filler pipe, or other suitable secure attachment.

Cord Attachment:

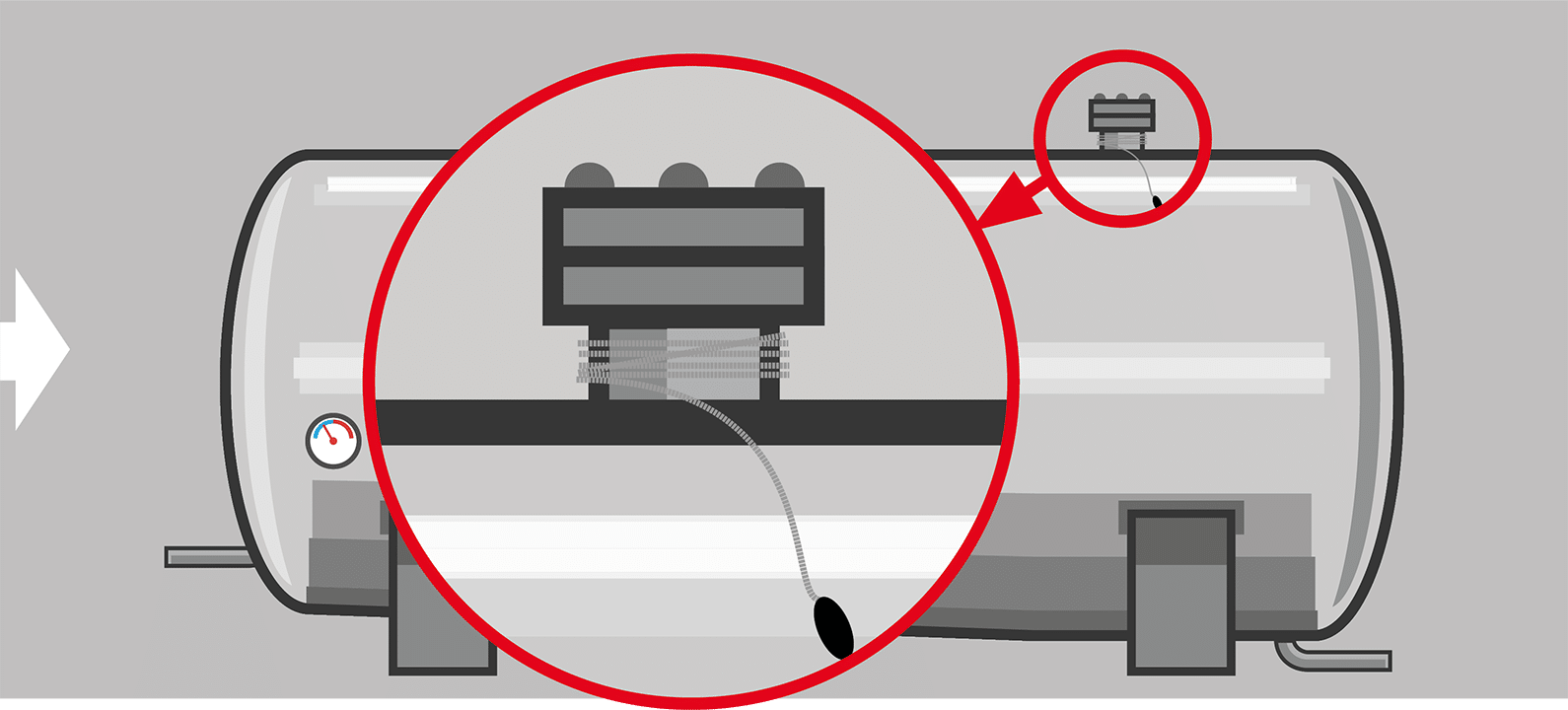

It is important that the cord is secured securely to the outside of the tank for retrieval of the Aquafighter for inspection and replacement, without chance of damage to the cord during service. In certain instances, e.g. when the tank inlet is via a metal threaded cap, it may not be as simple to secure the cord without fear of the cord being cut by the thread. A couple of examples are shown of how users have successfully and safely secured the Aquafighter in those instances:

- The first shows a cable gland fitted to the tank cap, through which the Aquafighter cord passes from inside to outside

- The second shows a metal ring affixed to the underside of the tank cap. In this case the cord is attached inside the cap and will not be visible on the outside of the tank once installed

IMPORTANT:

The pouch should be kept handy to be utilized to contain the used Aquafighter product at time of change-out.

Inspection:

The Aquafighter must be inspected regularly, e.g. monthly, for water content / water absorption. If less than 50% of the Aquafighter has turned red, it can be returned to the tank. If more than 50% of the Aquafighter has turned red, replacement is recommended.

Replacement:

When more than 50% of the Aquafighter filter has turned red, replacement is recommended. Used Aquafighter must be safely placed in the bag it was delivered in, or similar, and disposed of at an approved collection point, e.g. the local recycling centre. The used Aquafighter filter will consist mostly of water, but small amounts of diesel can remain, and it should therefore be treated in the same way as other waste fuels, lubricating, or hydraulic oil, fuel and paint residues.

Procedure for use on vehicles, construction machinery, pleasure boats, etc:

Common to fuel tanks on vehicles, construction machinery and pleasure boats is that they have an internal tank structure that includes a float and possibly a fuel pump (“feed pump”). To prevent the Aquafighter from interfering with these components or the fuel supply it is strongly recommended to remove the Aquafighter from the tank when the vehicle, machine or boat is in operation. However, it is highly recommended that the Aquafighter remains in the tank continuously outside of those operating periods, and is regularly inspected for water absorption.

Removal during operation:

Before starting the engine of the vehicle / boat, the Aquafighter filter MUST be removed from the tank, inspected for water content (see section 7) and placed back in the airtight bag. Allow the Aquafighter to drip off excess diesel before placing it in the bag.

Re-installation:

As soon as the vehicle / boat has ceased operation the Aquafighter should be re-installed to project the tank and keep the fuel water free. Follow steps 2-6.

Note:

- When handling the Aquafighter with a risk of diesel exposure, gloves and other adequate protective equipment should be used to avoid contact with skin or eyes. In case of diesel spills and/or diesel getting in contact with the skin or eyes, the procedures described in the diesel safety data sheet (SDS) must be followed

- When using an Aquafighter for the first time, there may already be a volume free and/or dissolved water in the diesel tank that will be quickly absorbed. Consequently the Aquafighter will reach its maximum capacity and 50% red colour far sooner than normal during this first installation. It is therefore recommended to inspect the Aquafighter on first time installation after maximum of one week. If the Aquafighter needs to be replaced after a week, add a new Aquafighter into the tank and perform a new inspection within a week. Eventually it will take longer and longer between each required replacement with a new Aquafighter. This simply means that the diesel in your tank has reached a level where water is no longer at harmful levels and the conditions for microbes to grow has been removed.

- In some applications components in a diesel tank can be damaged by use of the Aquafighter whilst the tank is in motion during operation. (ONLY USE WHEN TANK IS STATIONARY)