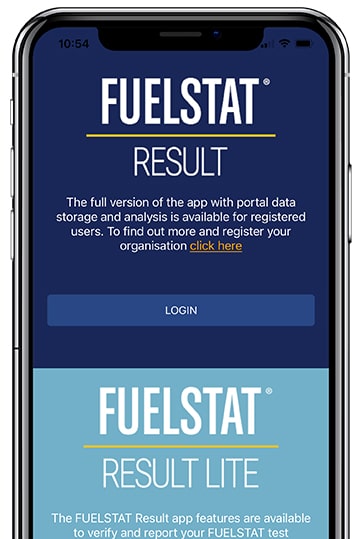

Make Informed Decisions on the Spot

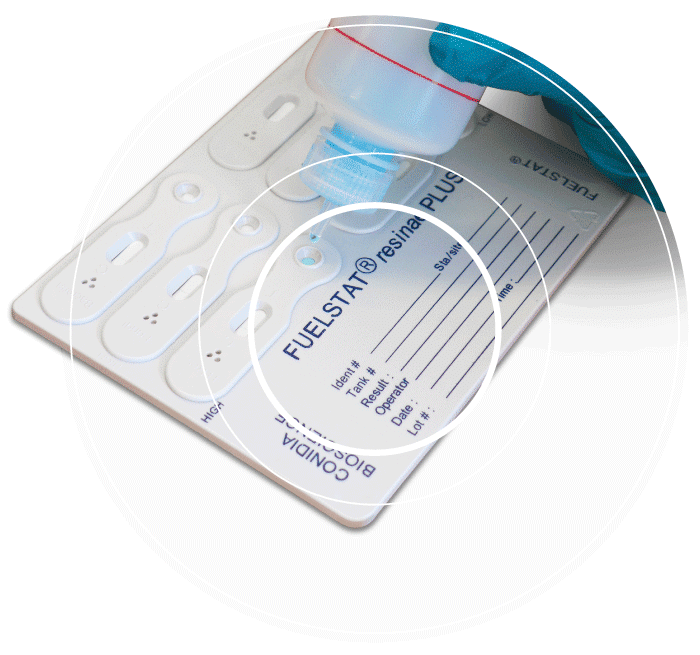

FUELSTAT®: instant results for Microbial Contamination in Diesel without delays.

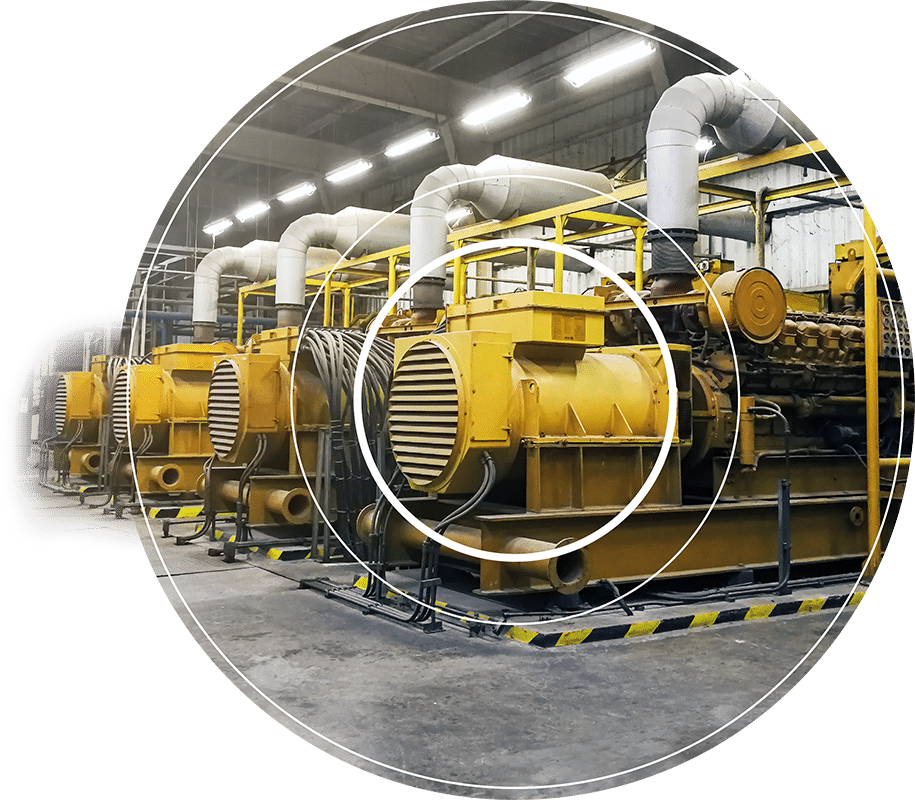

The performance of vital backup power generation assets can only be determined when they are required most, in times of main power supply failure. As such it is highly important that the fuel supplying such important equipment is maintained to the highest quality.

One of the biggest risks to diesel fuel is contamination from microbiological growth. There are certain species of microorganisms that are robust enough to survive in diesel fuel and their life is sustained by even the smallest amount of water. Water gets into fuel mainly from condensation, even in well maintained tanks, from temperature fluctuations night to day, hot to cold etc.

The introduction of FAME (Fatty Acid Methyl Ester), or otherwise referred to as bio content, to modern diesel has been referred to in standards from many countries such as British Standard (BS 5410-3:2016) as having an adverse effect on the quality and life expectancy of fuel and as such makes recommendations regarding the testing of fuel servicing critical, backup power generators. Whilst it indicates that equipment with permanent fuel polishing equipment attached should be tested every six months it recommends that those without such equipment should be tested quarterly.