Retail Filling Stations

On the spot testing for “diesel bug” is good for business and profits in Retail Filling Stations.

The last point of the supply chain prior to delivery to consumers is the hardest place in relation to diesel supply. Any potential unscheduled downtime of a stations ability to pump fuel can be the difference between a profit or a loss, success or failure.

Diesel fuel, especially biodiesel and increasing low sulphur diesel can be contaminated by microorganisms where there is even the slightest amount of water in the fuel. Commonly known as ‘diesel bug’ and if transferred to consumer vehicles can cause serious issues to injectors, filters, pumps etc.

If left undetected in the storage tanks diesel bug can corrode tank walls, which means environmental risks in addition to business disruption.

Underground storage tanks are the most difficult areas in which to remove free water, which happens to be the central cause of microbial contamination so testing can help with a more cost-effective maintenance program being undertaken.

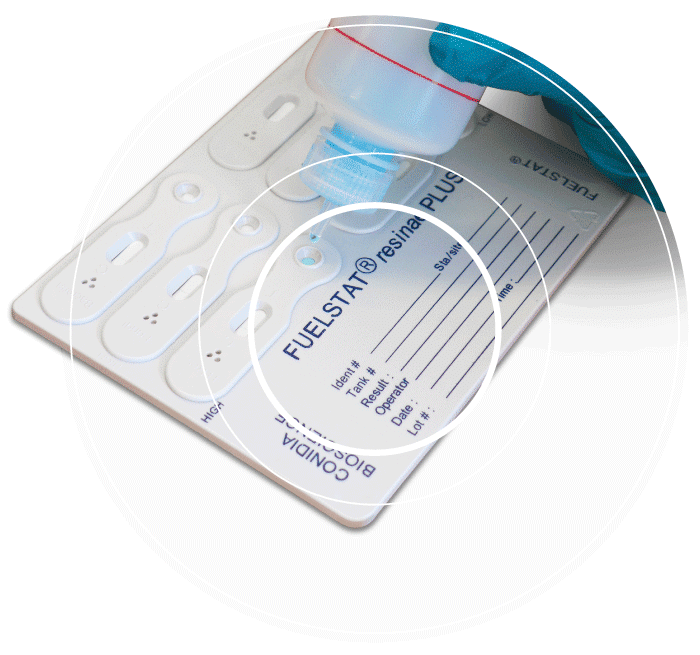

Used as a tool to assess tank health and enable swifter, more cost effective, on-site maintenance to take place as any identified contamination can be treated in one visit thus reducing the risk to the site and ultimately to the consumer.

In such a litigious environment, random nozzle sampling can provide a retail site with the satisfaction and safeguard that no contamination is being passed to consumer.