Marine fuel testing for microbial contamination: a practical guide

In many of these cases, the fuel was on-specification and didn’t have dangerous levels of contamination when it was uploaded. Microbial contamination can grow quickly in short time periods – so testing your marine fuel is very important.

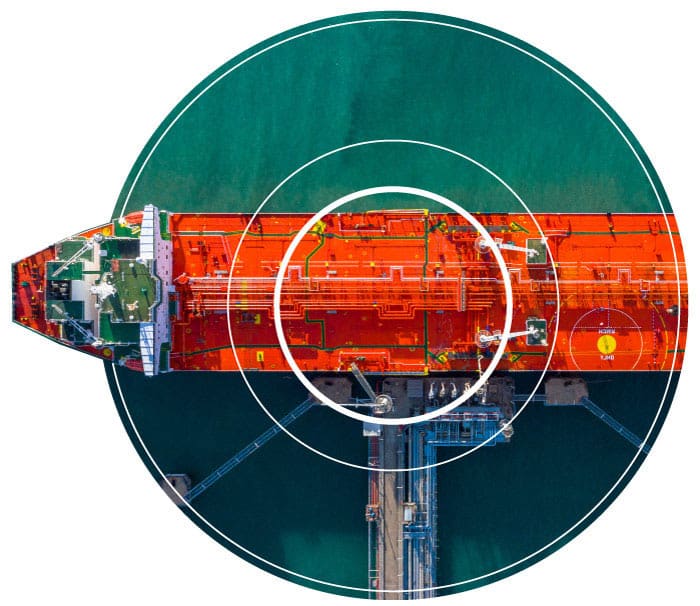

FUELSTAT® off-shore marine fuel test – FUELSTAT Diesel Plus (FMD8)

Test for all known microbes that are dangerous to fuel in just 15 minutes

What are the options for testing marine fuel?

Generally, an on-shore test takes several days and is conducted in a sterile laboratory by highly-trained specialists.

Alternatively, there is a method called thixotropic gel that can be done on-site but also requires the same incubation as with all CFU growth tests.

A fast test that can be carried out off-shore using specialised equipment. Extensive training is required.

A rapid modern type of on the spot test, often used when operational at sea, which can be carried out without any special equipment and without needing extensive training.

We’ll take a closer look at all three marine fuel tests after a quick note regarding on-shore testing.

Learn more about FUELSTAT®

See how FUELSTAT® can save you time and money by testing for marine fuel contamination early.