Diesel Bug 101

What is it? How to avoid it.

If so, you need to be aware of the growing danger of diesel bug. Recent changes to fuel such as the addition of biodiesel mean that, although it has clear environmental advantages, it is increasingly likely to affect your business.

Left unchecked, it can lead to operational issues and even serious corrosion. That means a big hole in your diesel tanks—and an even bigger one in your wallet.

Immunoassay antibody tests are the quickest and easiest available today, reliably detecting the specific microbes that threaten fuel.

Equipment: Requires minimal equipment and zero investment beyond simple test kits.

Location: Can be conducted on-site, so fuel does not need to be sent anywhere.

Time: Gives test results within minutes.

Level of testing: Only searches for microbes that are threatening to fuels. This means that the user doesn’t need to take any special sterility measures on-site.

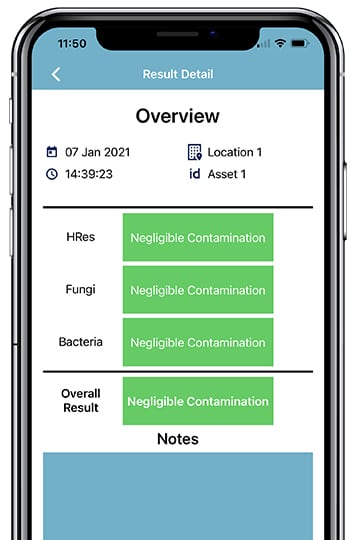

Other considerations: results are given in a ‘traffic light’ green/amber/red system. This means that you don’t have to spend time calculating levels of contamination. You get an instant readout of negligible/moderate/heavy contamination according to industry standards.

Immunoassay antibody tests like FUELSTAT® also let operators test diesel fuel at the point of uploading. You can then ensure that you aren’t accepting moderately or heavily-contaminated fuel.

ATP testing detects any living microorganism present, but also tests for microorganisms that aren’t dangerous to fuel. This can lead to misleading results that result in assets being taken out of operation for days unnecessarily.

Equipment: Requires a ‘reader’, and this equipment costs thousands of dollars/pounds.

Location: Testing is not conducted on-site, so fuel samples have to be transported as a hazardous good, at high cost.

Time: The tests themselves take minutes, but as they usually take place off-site in a laboratory, the process of transporting samples adds days to the process.

Level of testing: ATP is ‘catch-all testing’ that finds all living microbes, including those that aren’t directly threatening to fuel at that time, such as E.coli and the flu. This means results can sometimes be overstated or misleading.

Risk: Overstated results can mean positive contamination alerts. This typically leads to re-testing of fuel, or expensive biocide treatment when it isn’t actually needed.

CFUs are laboratory-based tests that are based on 19th century Pasteur technology. While the tests themselves take 4-10 days on average and it’s very difficult to stop background contamination entering the sample, so misleading results can occur.

Equipment: Requires a laboratory-quality incubator.

Location: Testing is not conducted on-site, so fuel samples have to be transported as a hazardous good, at high cost.

Level of testing: CFU is ‘catch-all testing’ that finds all culturable microbes, including those that aren’t directly threatening to fuel, such as E.coli and the flu.

Other considerations: Tests are subject to cross-contamination, so require sterility measures e.g. transporting fuel in refrigerated containers.

Risk: Because CFU results can lead to misleading results, you may end up applying expensive biocide treatment when it isn’t actually needed. This means taking the asset out of operation for several days, potentially costing millions.

Additionally, CFU tests miss all microorganisms that do not grow in culture, thus there is also a risk of false negative results.