Do you need

a fuel test?

MINIMISING WATER

Fuel industry bodies like the Joint Inspection Group (JIG) have long recommended minimising the amount of water in fuel tanks. This helps to control contamination, so the advice continues to be helpful. However, in the case of biofuel, it has become more challenging to completely remove water from fuel tanks at all times.

FAME (Fatty Acids Methyl Ester)

FAME (Fatty Acids Methyl Ester) added to diesel is hygroscopic, meaning that it absorbs and retains water more than ordinary diesel. In diesel with FAME, free water is typically found at the bottom of a tank, but there’s sometimes a hazy layer of suspended water above it. Although this hazy fuel can still be drained away, it’s much more difficult to expel the water droplets left behind in the fuel.

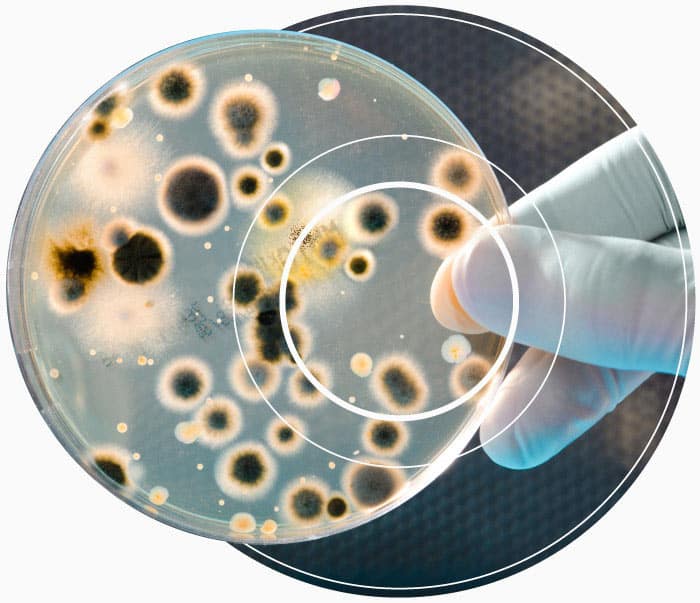

blockage & corrosive effects

Prolonged, heavy microbe infections are very costly because of their ability to block filters and injectors and cause corrosive effects. Businesses need to take assets out of operation, repair mechanical parts, replace or treat the fuel itself, and de-contaminate fuel systems.

Polishing & biocide application

The fuel itself may need both fuel polishing and biocide application if it is to be saved for reuse. Even low/moderate contamination levels can lead to filter clogging, pump and injector wear, plus metering and gauging problems that affect fuel quantity indication systems. This can lead to expensive operational and commercial issues.

proactive strategy

Many users have concluded that taking action with microbial contamination early on is the cheapest and best solution. Investing a small amount in a proactive strategy can mean huge savings in the long run.

fuel maintenance

As an operator, you need a fuel maintenance plan that incorporates a fuel test. You can test fuel with various tests on the market that gauge the levels of contamination in the tank, fuel system, or supply chain.

Testing methods

Each testing method has pros and cons regarding the time involved to obtain results, the cost, the equipment and expertise. When developing your fuel maintenance plan, consider these different methods along with the contamination risks that apply to your situation.