A guide to aviation fuel testing for contamination

Aviation fuel can potentially be contaminated by several influences. These include particulates in the fuel, water in the fuel, and other types of fuel that use the same delivery system. They can also include microbial contamination, which we will discuss in this article.

Aviation fuel, also known as jet fuel, is vulnerable to microbial contamination from microorganisms in the surrounding air and surfaces. Left to proliferate unchecked, these microbes can cause mechanical and systems failures, operational problems such as aircraft being grounded, corrosion and in extreme cases total engine failure.

IATA (International Air Transport Association) deems microbial contamination in jet fuel as an important enough topic to have produced in its 5th Edition a 60-page guidance document, which details the issue, indicates where risks are highest, explains the approach and gives guidance and information on dealing with issue.

JIG (Joint Inspection Group) gives similar guidance to the fuel supply chain that it represents.

Read on to learn more about fuel contamination and the tests that can detect it.

What is aviation fuel microbial contamination?

Aviation fuel systems are ideal habitats for these organisms. Not only are these systems often warm and humid, but they also provide food for microbes in the form of hydrocarbons that are in the fuel.

If these microbes (also known as ‘bugs’) are allowed to proliferate unchecked, they can block fuel filters and cause gauging problems. In fact, they can even induce corrosion to such extent that they can damage the aircraft’s tank structure.

Because of these risks, aviation fuel testing for microbial contamination has become standard operation for all users of aviation jet fuel. It is typically part of a more comprehensive system of managing the fuel systems from beginning to end, which is known as fuel husbandry.

What happens if microbial growth in aviation jet fuel goes unchecked?

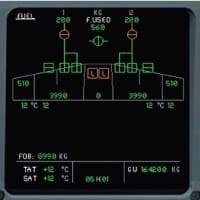

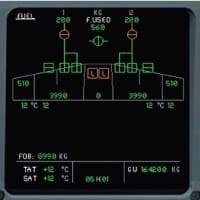

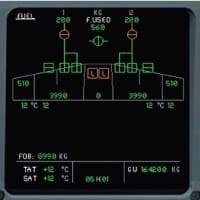

Issues with Fuel Quantity Indication (FQI) probes

A biofilm from the contaminated fuel can coat the probes and cause them to send out different electrical signals, indicating in the cockpit that there is a fuel issue in a tank. This can ground an aircraft, and if there’s not a replacement probe at the next destination, there’s a risk that the aircraft may be grounded until a replacement is supplied and fitted.

Filter Issues

Aviation jet fuel contamination can block filters, and operationally this could mean that a filter bypass warning may light up in the cockpit, particularly at take-off. Under full power at take-off, the full force of fuel may be restricted by a clogged and contaminated fuel filter(s), and this could cause the warning light to illuminate.

These filter issues can cause costly operational delays. Not only do the blocked fuel filters need to be addressed, but further investigation and rectification of the fuel system may also be required.

Microbially Influenced Corrosion (MIC)

Most seriously, aviation jet fuel microbial contamination can cause corrosion if left unchecked. Acids produced by the contamination can eat through both the outer protection of the structure’s surface and the structure itself. And because jet fuel is kept in the wings and other important parts of the structure, it can be catastrophic to the integrity of the whole aircraft.

When should I conduct aviation fuel contamination testing?

This will give you a good general understanding of the condition of your fuel and fuel tanks.

For most operators, the objective of testing is to catch aviation jet fuel contamination at the earliest stage before any operational issues occur. By doing so, they can prevent heavier contamination, leading to issues such as corrosion and related consequences. Catching fuel contamination early is important, but also requires you to assess your risks and the known history of your fleet.

FUELSTAT® 15-minute aviation fuel test kit

Immunoassay antibody testing for all known microbes that are dangerous to fuel.

How do the testing methods measure microbial contamination?

Under this method, contamination levels are stated in units of cfu/ml (colony forming units per millilitre) in water and cfu units per litre in aviation fuel. However, new technologies are now available, including immunoassay lateral flow device techniques, ATP analysis, and molecular methods.

Many operators will separately test different the fuel itself, and any water found within it. Water always forms a separate layer or ‘phase’ because it has a different density.

There’s no absolute or consistent correlation between the number of microorganisms in the water phase versus the amount in the fuel phase. However, there’s usually at least 1000 times more microbial contamination found in the water phase.

How are test results interpreted?

Green

is the lowest level, signifying a negligible level of contamination. The recommended guidance is to continue monitoring the fuel, with no further action required.

Yellow

represents moderate contamination. The guidance is that a re-test is conducted. If fuel contamination is confirmed, the fuel user should treat the fuel with biocide. This should be followed with further testing and filter changes at a later stage.

Red

means heavy aviation fuel contamination. The recommendation is re-testing, tank emptying and cleaning, biocide treatment and/or fuel treatment, re-testing, and filter changes.

How to approach fuel husbandry

In order to avoid the inconvenience and cost of a contaminated fuel tank, a multi-disciplinary approach to fuel husbandry is needed.

An aircraft fuel husbandry regime should consist of three main activities as well as regular structural checks on the tanks itself:

- Regular water drainage and water checks, because microbes thrive in water

- Test of the fuel in every tank, (annually at the very least)

- Appropriate fuel tank treatments, if contamination is found

The risk of contamination is increased in hot, humid conditions, especially where fuel comes from a source that has fewer quality control checks. Each airline should, therefore, carry out its own risk assessment to establish an optimum regime.

Read more >> Aircraft Fuel Testing

FUELSTAT® 15-minute aviation fuel test kit

Immunoassay antibody testing for all known microbes that are dangerous to fuel.

Do I need any special aviation fuel testing equipment?

CFU methods such as IP385 laboratory methods or a thixotropic gel method, the latter of which can be used on-site, require an incubator. The test will also require an incubation period—times vary, but it always takes at least 24 hours, during which the incubator must stay at a fixed temperature.

Adenosine Triphosphate (ATP) testing requires a special reading unit called a luminometer that gives an indirect indication of contamination. Again, this process generally requires a higher level of training and experience to replicate successfully and is not likely to be completed on-site.

Immunoassay antibody testing is the modern method for finding contamination in aviation jet fuel, conducted using something called an immunoassay flow device. Unlike ATP or CFU methods, it does not require any special equipment or any extensive training. These tests are particularly well suited to on-site use. It gives results in 10-15 minutes.

GET IN TOUCH

FAQ

Is there any special handling required prior to fuel testing for microbial contamination?

Aviation fuel testing traditionally has had to be done in a totally sterile environment. And because testing facilities or laboratories are often based off-site, the fuel user must transport their fuel samples there as a hazardous good.

The only exception is immunoassay antibody testing. With this method, there are no special sterility measures to be adhered to, other than a clean sampling jar. And because the jet fuel test is done on-site (often under-wing), there are usually no transport issues to consider.

What sterility measures are needed for aviation fuel testing for microbial contamination?

With CFU and ATP testing methods, it’s possible that background contamination can interfere with the sample and give misleading results. The reasons for this are simple. These methods of tests will measure microorganisms present (not dormant/inactive forms), not just the microbes that have the potential to do damage to aviation jet fuel systems.

Microbes such as E.coli and the common cold can easily make their way into fuel, as they are present in the air and most surfaces. Even though they aren’t a risk to fuel, they can be picked up by CFU and ATP tests. The outcome can be a misleading test result—a diagnosis of contaminated fuel that is in fact a false alarm.

This happens because these testing methods effectively work by counting (directly or indirectly) the number of microbes found in the fuel sample, in the case of ATP it measures the concentration of ATP. When misleading results make the count larger, it can look like dangerous contamination before further testing is done.

The most modern method, immunoassay antibody testing, doesn’t need sterile conditions. It only searches for a specific range of microorganisms that can thrive and have the potential to do damage in aviation jet fuel and ignores any harmless microbes that have entered the sample.

You can complete immunoassay antibody testing under the wing in minutes, without the delay you would face when transporting fuel samples off-site. Because of this, it could be argued that immunoassay antibody test results are the most representative of actual tank conditions.

How does an immunoassay aviation fuel contamination test kit work?

Here at Conidia, we don’t use the traditional growth methods found in CFU testing, or the extremely technical procedures of ATP. Our jet fuel test is an immunoassay antibody test, which while still highly scientific, functions a bit like a pregnancy test.

This is important as the fungus, yeast, and bacteria we detect (including Hormoconis resinae, also known as Cladosporium resinae or jet fuel fungus) don’t just float around at the water/fuel interface—they stick to the bottom or sides of the tank. A sample, therefore, may not contain the dangerous microorganism itself.

FUELSTAT®: test aviation fuel straight from the tank in just 15 minutes

No special equipment required

All you need to use FUELSTAT® is a flat, clean surface, a pair of latex gloves and a 200ml fuel sample.

Easy to understand

Drop the fuel sample onto a FUELSTAT® and get a clear colour-coded visual result after a few minutes (similar to a pregnancy test).

Compliant with industry regulations

Results are given in a ‘traffic light’ format indicating negligible, moderate or heavy contamination ranges according to IATA guidelines.

Perfect for on-site testing

Testing jet fuel can be done on-site, in non-sterile conditions, so you don’t need to transport samples off-site.

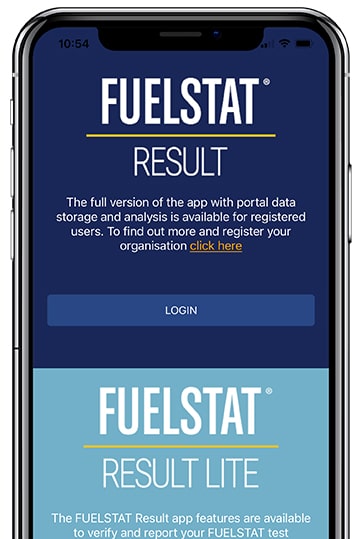

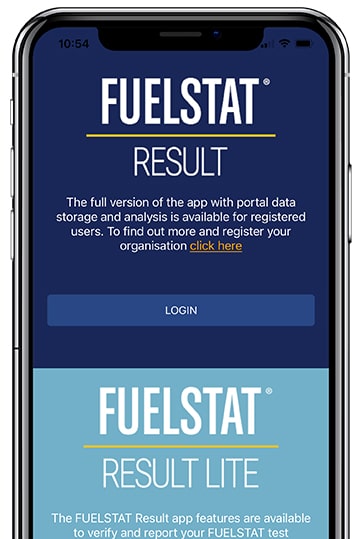

Fast, digitally-recorded results

The entire process takes just 15 minutes, and you can scan your test kit with our free smartphone app to instantly log your results digitally.

FUELSTAT® only detects the relevant fungi, yeasts, and bacteria if they have been growing in the aviation fuel. The kit will ignore any microorganisms that have blown in from outside and have been growing on other sources—so there’s almost no chance of misleading results.

Get a FUELSTAT® aviation fuel test kit

Use FUELSTAT® to test for aviation fuel contamination and avoid costly mechanical and operational problems