Conidia Bioscience acquire global distribution for Aquafighter®

AQUAFIGHTER®

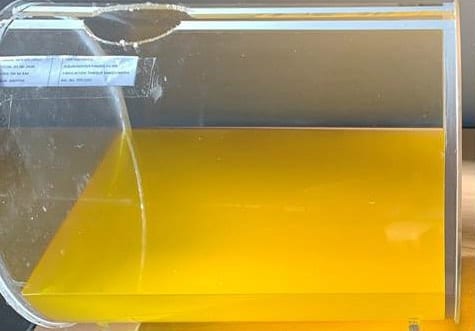

Aquafighter® actively removes bound, suspended and emulsified water out of diesel fuel directly in the tank and keeps it water-free at all times.

How does Aquafighter® work in the fuel tank?

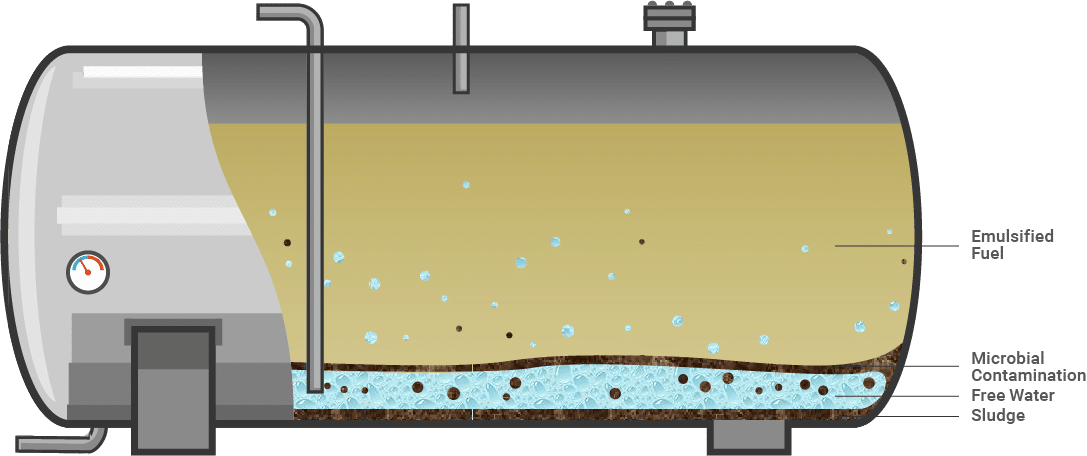

Aquafighter® is effective in reducing and removing water inside the fuel tank. This is accomplished through 3 indispensable actions that are necessary to achieve the desired fuel purity and consequently provide tank protection:

- Demulsifies water by physico-chemical adsorption of water molecules to less than 65ppm total fuel water content with maximum efficiency. (Aquafighter causes water to release naturally from fuel and it achieves this without adding to or altering the fuel, unlike certain fuel additives would do. After market additives can cause corrosion themselves)

- Attracts & Captures water immediately upon release from the fuel molecules

- Isolates water in its protective gel to permanently segregate it from the fuel & tank environment so your fuel & tank is protected at all times. (Aquafighter will encapsulate the water preventing corrosion, microbial growth & re-emulsification until it is removed from the tank)

Note: With biodiesel, fuel becomes significantly more hygroscopic, which means it attracts water. Thus, the fuel becomes emulsified with water rather than to allow the water to separate to the tank bottom.

FREE White Paper:

Find out how Aquafighter® water removal filters and FUELSTAT® test kits can be part of the solution for a cost efficient fuel management programme.

Aquafighter® performs four actions in your diesel tank

First, Aquafighter® causes the immediate separation of bound water molecules from the fuel molecules upon contact.

Secondly, Aquafighter® actively captures the formerly bound/emulsified water inside the fabric membrane.

Thirdly, Aquafighter® secures and isolates the water inside the gel neutralizing it from any potential damage to your tank, fuel, filters or engine.

Finally, Aquafighter® repels the clear and bright “better-than-spec” fuel back into the tank.

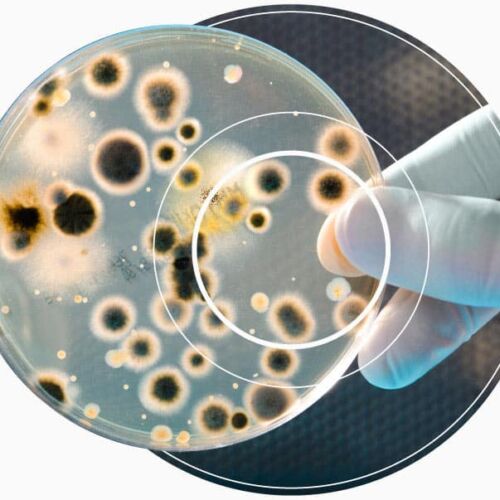

FAME, also known as bio-fuel, is more hygroscopic than traditional fuels—in other words, it attracts and holds water. This means that it’s more prone to produce condensation issues in fuel systems. And increased condensation means better conditions for the growth of diesel bug, also known as diesel fuel fungus.

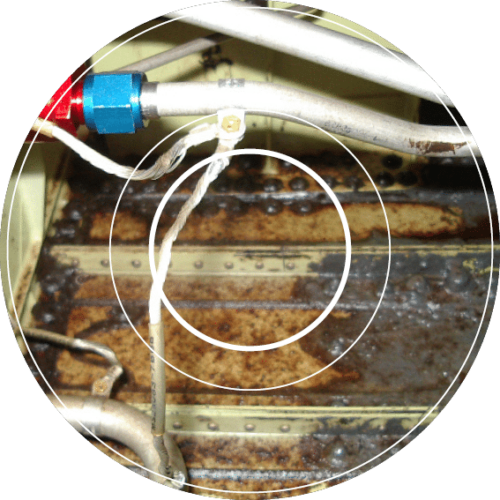

Microbiological contamination often creates operational issues that can disrupt the use of an asset, for example:

- A tank builds up microbial matter until it can no longer be used and requires cleaning

- A generator engine fails to fire up because its filters are blocked by contamination

- A fuel quantity indicator functions incorrectly because of a microbial biofilm coating the probes that read the fuel levels

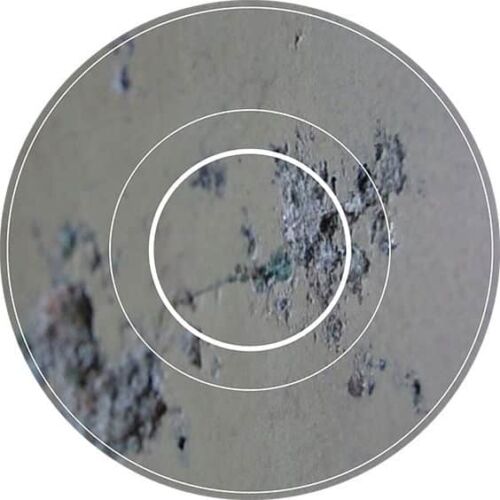

- In a very serious scenario, microbial contamination can seriously damage tanks themselves. Left unchecked for too long, it can lead to Microbially Influenced Corrosion (MIC) of the tanks because of the acids it produces.

When microbial contamination reaches severe levels and produces these acids, it can lead to serious safety and environmental risks. For example, a large tank could develop a leak so that fuel escapes into the ground. Or a severe blockage could cause engine failure, and even put human lives at risk. Learn more about AquaFighter Lite.