Storage Tanks and Microbiological Contamination – reducing risk in a pandemic

Microbiological contamination (fungi and bacteria in fuel) is a serious risk to tank storage operations, especially if fuel turnover is lower. However, there are some fast, economical steps you can take to prevent unnecessary costs and risks to business.

Mark Busch, Sales Director – US, Conidia Bioscience

Organic materials

Like a piece of bread, fuel is an organic substance. Also like a piece of bread, fuel can go moldy. Mold, which along with yeast, is a form of fungus and grows over time. The longer it is stored, therefore, the greater the risk that this naturally occurring microbiological contamination will thrive.

Fuel inherently contains water in some form as soon as it leaves the sterile environment of the refinery. Water can be picked up at any point in the supply chain; in pipelines, storage tanks and fueling trucks. It can also naturally enter storage tanks due to condensation, making it impossible to keep it completely out of the supply chain. Of course, many companies will have sophisticated wet stock management with water sensory equipment, but even the smallest amount of water (far from the levels these mechanisms can detect) can improve conditions for microbiological growth.

What is the level of risk?

During the pandemic, national lockdowns have created a slump in the use of fuel across aviation, marine and land transport. Grounded aircraft, working from home, school closures, and decimation of the cruise industry have all contributed to reduced fuel consumption. Even where fuel turnover remains high, additional care should be taken that incoming fuel supplies are not contaminated.

Rachel Harrison at Fueltek Ltd, said: “The ‘diesel bug’ is something that anyone storing fuel in bulk is generally aware of, but maybe not of the increasing risks it poses.”

The really bad news is that microbiological contamination is transferrable along the fuel supply chain. The challenge is to manage the levels of risk efficiently and economically. Of course, while we are living through a pandemic, consideration also needs to be given to the risks posed to staff and the public by carrying out unnecessary activities.

Fuel testing, fast and simple

Although it is good practice to remove as much water as possible from fuel supplies, coupling this with a sound testing regime will provide a clear picture of what is going on inside storage tanks. By understanding the level of contamination in a storage tank, smarter more economical decisions can be made about what actions to take without just decanting the fuel, cleaning tanks and adding an additive such as biocide at first suspicion of contamination. Estimates that we hear for cleaning and treating an underground storage tank can be up to as much £20,000. Any alert system that helps earlier intervention to apply a cheaper solution is, therefore, almost certainly a good thing to consider.

A testing regime developed over time to optimize testing frequency will reduce the risk of major impact from microbiological contamination. There are two broad options for testing: sending samples to a laboratory or using onsite test kits. While sending fuel samples to a laboratory may appear to be the simpler option, the time to get a result can be significant, especially when laboratories are overwhelmed with other testing. Even in ‘normal’ times, however, testing of samples taken offsite needs to happen in a matter of hours as when samples are preserved in transit, the microbiological community may change and therefore the test results may not be representative of the microbiological growth in the tank. Samples need to be stored / transported under environmentally controlled conditions to ensure microbiological growth remains representative of the fuel from which the sample was taken, and conditions have not caused accelerated growth or damage to the microbes. Transporting fuel samples further increases the opportunity for cross-contamination and erroneous results. If you are looking to send samples for offsite testing, then ASTM 6469 offers a “Standard Guide for Microbial Contamination in Fuels and Fuel Systems”, which advises testing the sample within 24 hours and transportation on ice for most accurate results.

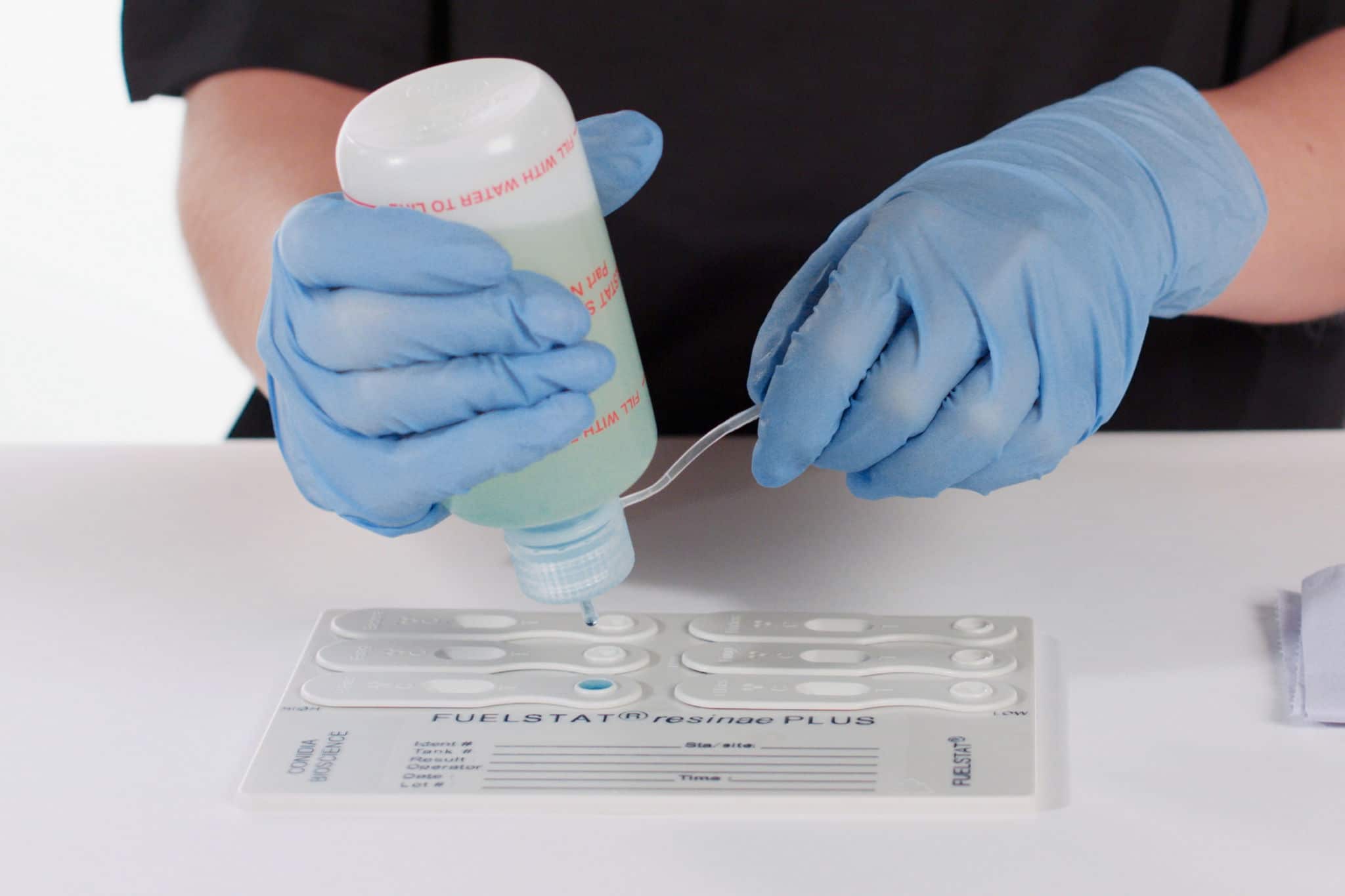

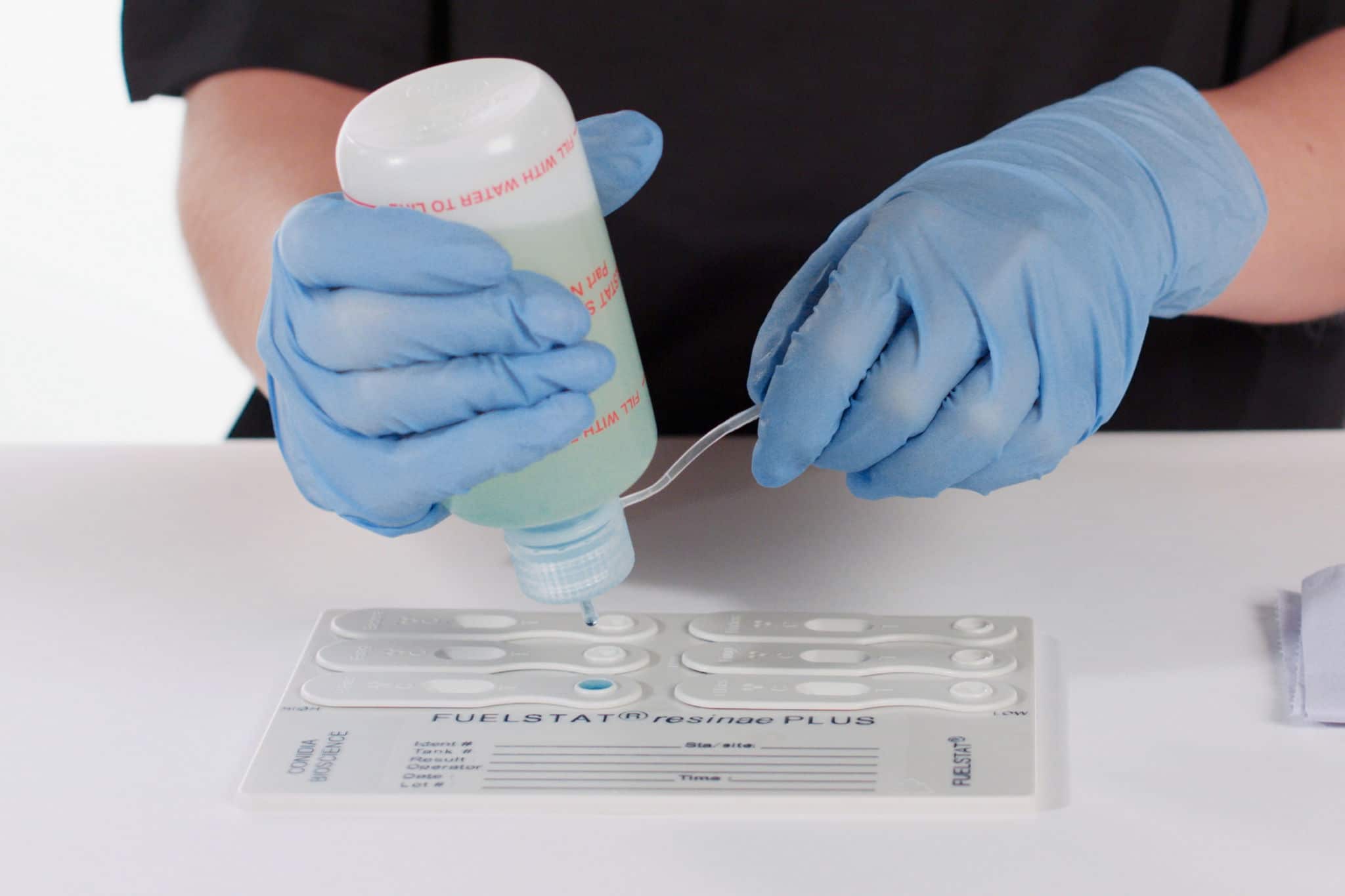

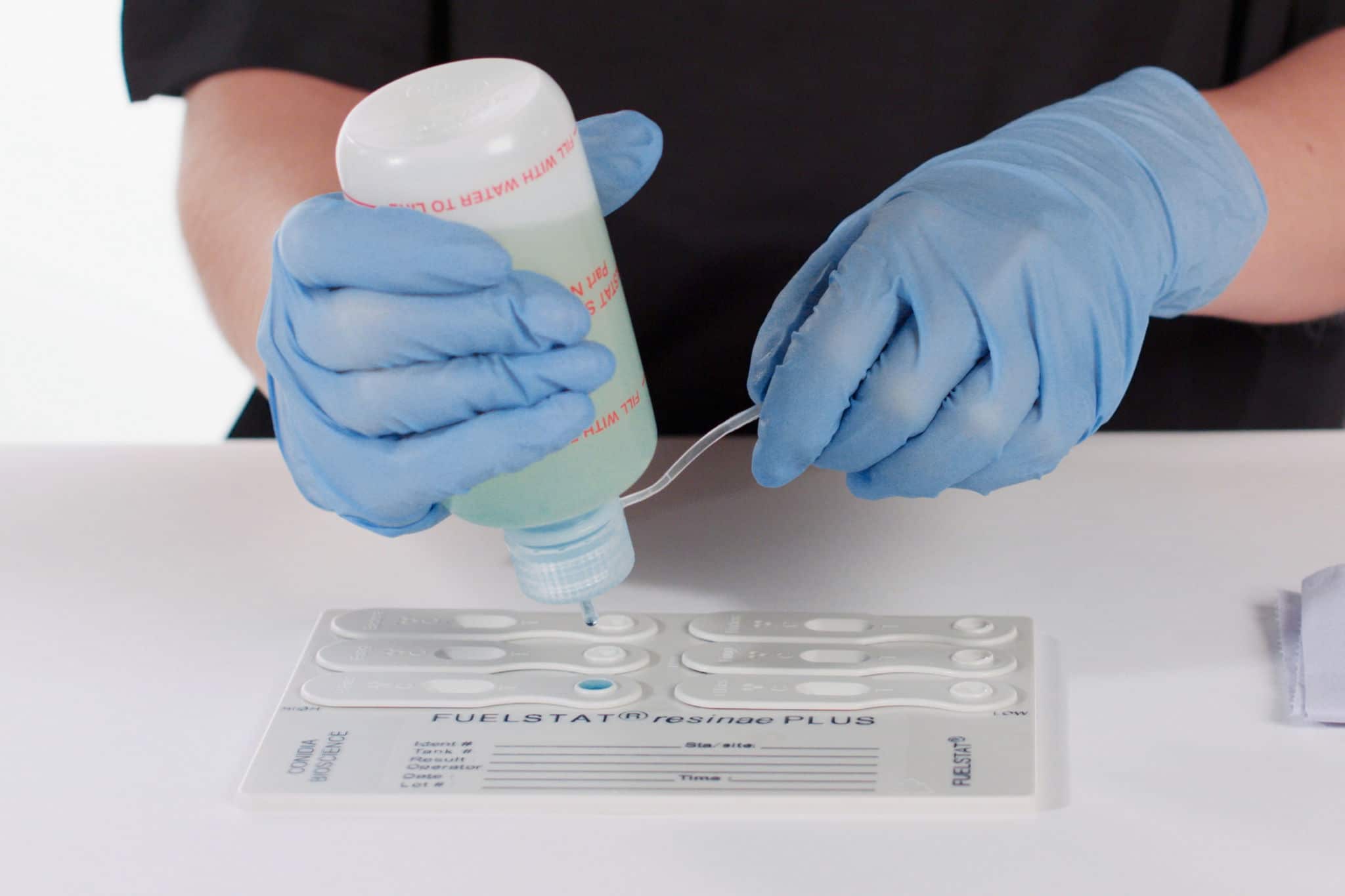

Onsite testing using antibody (immunoassay) test kits, on the other hand, is incredibly simple and economical. There are a few basic rules to follow for any testing process, including ensuring sampling points are effectively cleaned, sampling equipment is cleaned between each sample extraction, and, ideally, a new sampling container should be used for each sample to minimize risk of cross-contamination. Other than that, the process is remarkably straight forward.

Rachel Harrison continued: “A regime of good fuel husbandry and management should be in place, and antibody test kits are a useful, inexpensive tool to support this. We have used the antibody testing kits extensively to satisfy our customers’ demands to ensure they are using clean uncontaminated fuel. They have proved reliable and successful and have added another income stream to our organization.”

What are antibody test kits?

Antibody test kits are a well-proven method of identifying specific molecules and have long been used in the medical industry. Today, many people are aware of the term as they are used to test for COVID-19 infection, but they are used in many other areas, such as pregnancy testing, for example. These kits use antibodies that bind to a specific antigen to detect its presence and produce a measurable signal in response to this binding that can be used to assess fuel contamination levels. Microbiological contamination correlates to the activity of microbiological growth in the sample. The amount of antigen produced when microorganisms grow in the fuel is measured for a known sample size. This correlates to the number of active microorganisms in the fuel and produces a fully accurate indication of contamination levels.

Simple, cost-effective testing, easily implemented in the field

Single use immunoassay fuel test kits such as FUELSTAT® from Conidia Bioscience clearly and accurately show levels of contamination for major aerobic fuel contaminates. They can be used by a single person with minimal training, requires no capital equipment, are compliant to ASTM D8070, and are widely used and recognized by the aviation industry along with major international oil companies (IOCs), and large machinery manufacturers. If the results app is installed on a mobile device, this can further be used to get an instant digital verification of test results and to store and share them with appropriate personnel, wherever they are located.

The speed and ease of using immunoassay test kits mean the mitigation of contamination risk can be easily managed in day-to-day operations. Using this straightforward method of onsite testing, tanks can be protected from the risk of damage from microbiological contamination while unnecessary cleaning or biocide dosing of tanks that do not have significant levels of contamination can be avoided, reducing both time and cost of operations.

During the pandemic, increasing testing frequency to allow for the greater risks posed to the fuel supply chain from yearly to quarterly may increase testing costs from $100 to $400 p.a. but if this allows such early detection of contamination so that only a biocide and/or fuel polishing exercise is required, and the cost of constantly changing filters, tank cleaning, fuel disposal or downgrading are avoided, then the savings and operational uptime benefits are significant and relatively easy to achieve.

Summary

With no upfront costs, in-depth training or special handling required, immunoassay test kits offer an economical way to bolster fuel husbandry regimes and protect from unplanned maintenance. While the impact of the pandemic has lowered fuel throughput and, therefore, increased risk of contamination, more regular testing using these test kits will help lower maintenance costs and reduce business risk. Ultimately, they offer a remarkably simple, fast and low-cost way to make smarter maintenance decisions and mitigate the risks of contamination.

If you would like to find out more about the issues surrounding microbiological contamination, then see here: