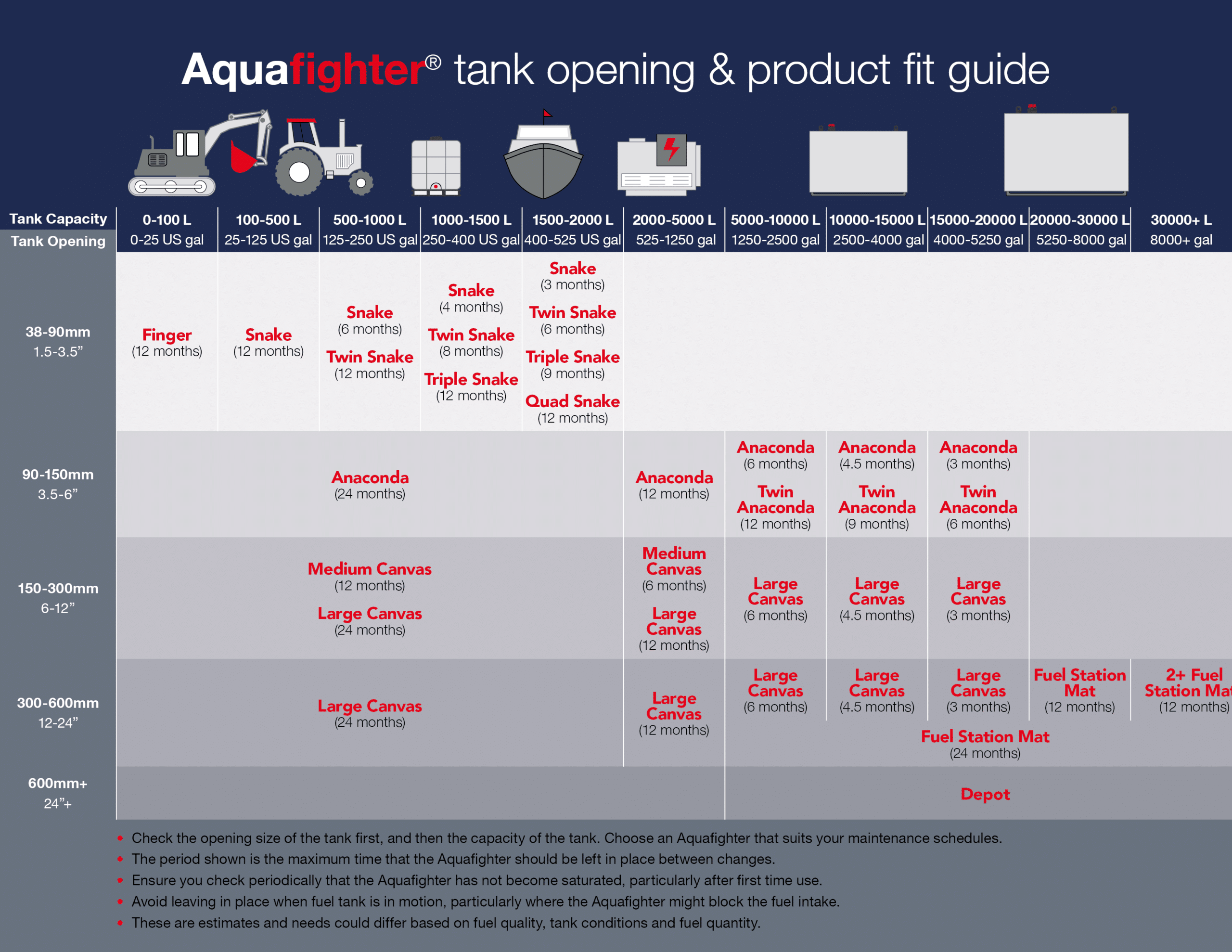

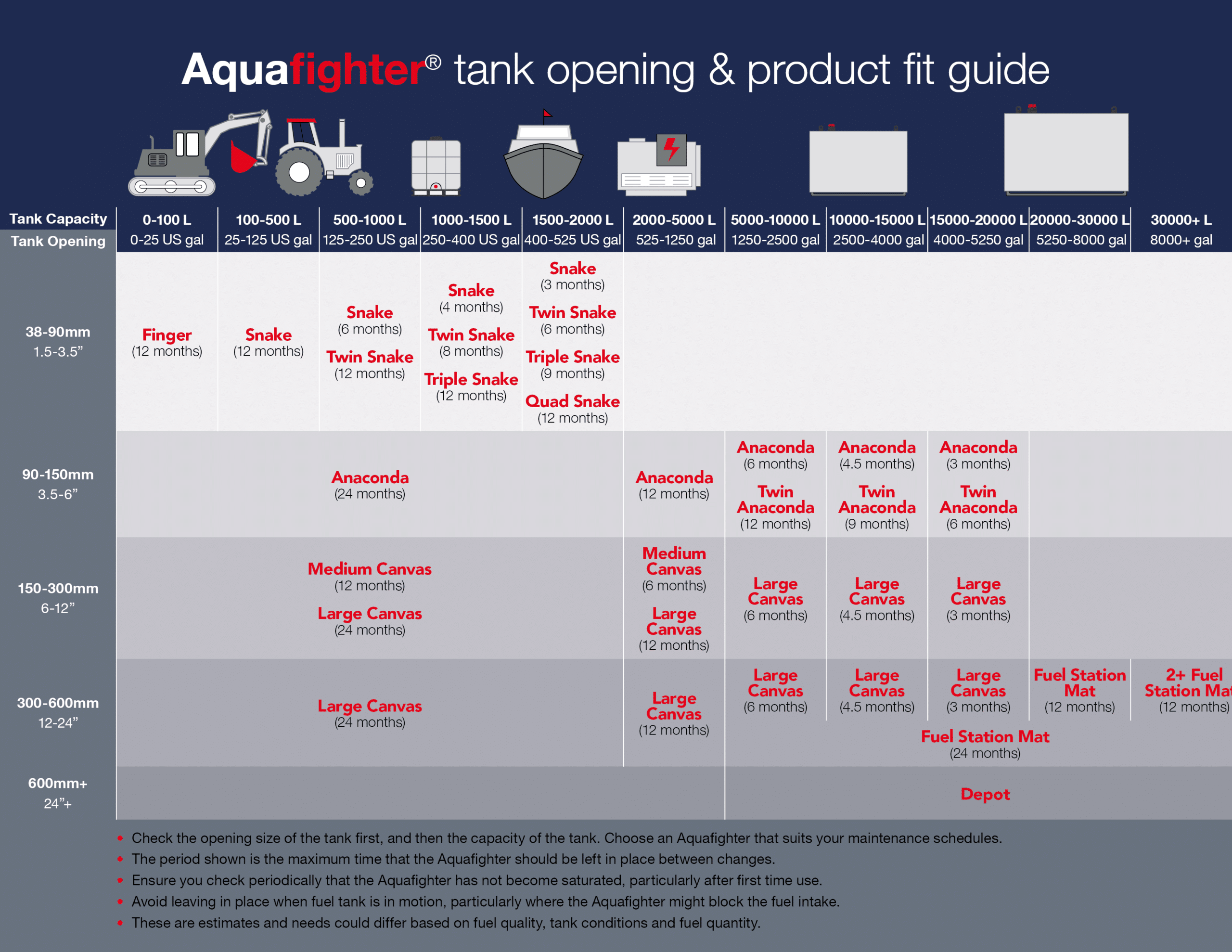

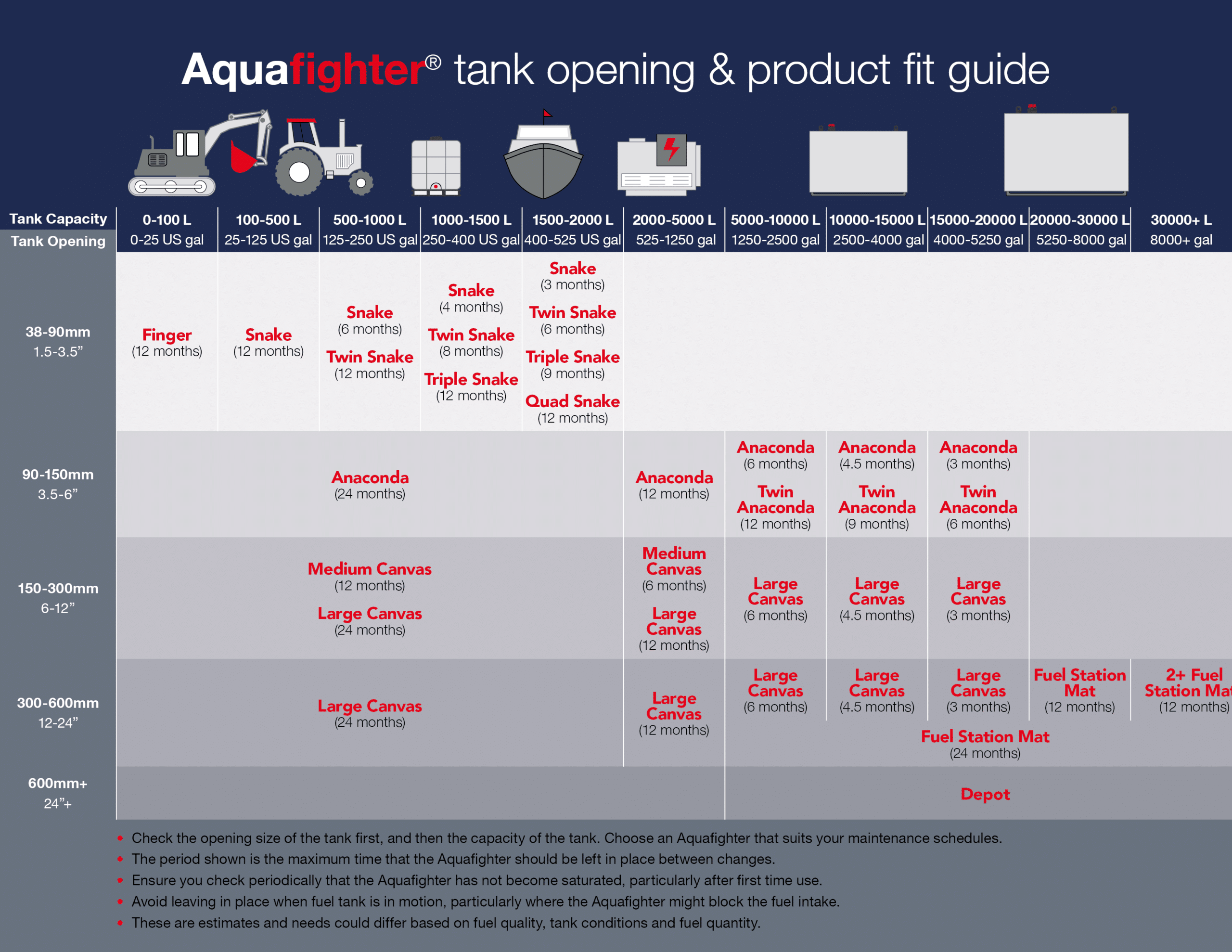

The proper Aquafighter product size is based mainly on the following:

- Check the tank size opening available along with the total tank capacity

- Choose an Aquafighter product that will suit your maintenance schedules based on the approximate total water capacity of each Aquafighter product

- Monitor monthly to ensure that the Aquafighter product has not become saturated. You will have to check more frequently when used for the first time where the condition of the tank is unknown

- Ensure that the Aquafighter product does not block any fuel intake. Avoid leaving in place when the fuel tank is in motion, e.g., operation of boats, vehicles, etc.

- Frequency of Aquafighter replacement will differ based on fuel quality, tank conditions and fuel quantity, but do not exceed the suggested maximum period of use for your tank capacity

We recommend that you install Aquafighter in a clean tank. Whether that be a new tank, or a recently cleaned tank, Aquafighter will sit partially suspended from the bottom of the tank to absorb any emulsified water that might be present. Water may enter a fuel tank from recent fuel delivery, vent pipes, condensation or even from a leak in the tank. Aquafighter has the power to absorb and chemically lock the water away from the fuel to help keep your fuel below 100 ppm total water content (this is lower than the maximum allowed concentration of water by any diesel fuel specification).

Aquafighter filters are designed to work in relatively clean tanks, dirty tanks can clog the Aquafighter fabric membrane and interfere with the water absorption process. Also, Aquafighter filters are not designed to remove dirt and bacteria that might be in your tank.

Whilst it might be tempting to just lower an Aquafighter into any problematic tank for it to immediately start removing any water, this is the not the advised process and represents an inefficient use of Aquafighter filters. Where it is not practical to clean a tank and replace the fuel, then best at least to drain any free water from the tank before installation, then check the Aquafighter daily and replace when over half full until a stable state of use is reached.

In summary, start with a clean tank and Aquafighter will keep your fuel clean (water-free).

Aquafighter or not, it is essential to maintain clean fuel in service tanks to avoid any downtime of equipment and costly maintenance.

Yes, Aquafighter works in the same way with petrol, however it should not be used with ethanol containing fuels.

The Aquafighter absorbent material that is inside of the specially engineered fabric membrane must come into contact with the water to chemically react with it. If there is a lot of dirt and bacteria build-up in the tank, the Aquafighter will not be as efficient, dirt and bacteria will affect the efficacy of the polymer by clogging the fabric, making it difficult for the liquid in the tank to come into contact with the active Aquafighter material.

Overall, water, dirt and bacteria will degrade your fuel and affect you tank. Ultimately it will find its way into your machines, equipment and filters. The costs of filter replacement, tank cleaning, additives, repairs and labour considerably exceeds the cost of Aquafighter. Clean your tank, install an Aquafighter product, and enjoy simple tank maintenance and great fuel quality.

Aquafighter prevents the very thing that fuel polishing machines are designed to fix. But Aquafighter is generally more effective, simpler to use and far more cost effective. Aquafighter will instantly start to chemically react with and lock away water molecules that are present in emulsified fuel. This is what makes Aquafighter so efficient. In contrast, fuel polishing equipment use physical force via filters or a centrifugal system to extract the water from the fuel, with varying effectiveness for free and emulsified water. Aquafighter is efficient in water removal inside the tank, without the need to recirculate fuel outside of the tank. A typical fuel polishing system would be expected to reduce the total water content of your fuel to around 200ppm. Aquafighter will typically achieve 65ppm, depending on fuel temperature.

In its first 2 years of development, Aquafighter was used exclusively with a European-based fuel company, one of the largest fuel companies in the world. During that period, Aquafighter was used to remove water from more than 1,700,000 litres of out of specification “water-logged” fuel, fuel that would have normally cost more than .60 USD per litre to dispose of. Rather than disposing of this fuel, Aquafighter was used to restore the fuel within specification for total water content. This represented significant savings! To confirm this, each fuel batch delivered to petrol stations was subjected to laboratory testing to confirm the low concentration of water and particulate matter – Aquafighter provided perfect fuel at less than 65ppm, 100% of the time. Since then, we have restored an additional 1,500,000 litres of their diesel fuel.

In addition, Aquafighter was installed into these same fuel station tanks after being fully cleaned and at the 6-month check-up, the fuel at the very bottom of every single tank was “Clear and Bright”. Upon laboratory testing a result of 60ppm was obtained.

We have also conducted fuel sample testing at the renowned Saybolt Laboratories in Sweden demonstrating an average total water content of 64ppm, one sample being at 40ppm. (All tests were performed on B7 biofuel samples with an initial average out of specification for water content 363ppm, prior to use of Aquafighter).

Aquafighter was first developed in 2015, since then more than 7,000 laboratory tests have been performed to confirm that Aquafighter removes emulsified water to less than 65ppm in every single tested sample. In addition, the first user of Aquafighter was a major fuel company in Europe. In the first 2 years, this fuel company restored more than 1,700,000 litres of emulsified fuel. This represents massive costs savings, considering just the avoidance in fuel disposal alone. In addition, in the reporting period between September 2019 and September 2020 at 170 fuel stations, a major fuel maintenance operator decided to use Aquafighter with the outcome of zero fuel complaints and a 50% reduction in pump filter usage. That was considered a major success and confirms that use of Aquafighter represents a net saving for fuel stations across the board.

Aquafighter will not remove large concentrations of sediments and sludge, it will not eliminate the presence of microbial growth and cannot restore already degraded diesel fuel. However, Aquafighter will remove emulsified down to concentrations as low as 65ppm and remove approximately 90% of small particles from your fuel. Since fuel degrading microbes require water to grow, once Aquafighter is in your tank it will stop bacteria from growing further and prevent fuel from degrading quickly. Therefore, we recommend that you clean your tank if it is dirty before use, and maintain an Aquafighter water-removal process in your tank to prevent microbial contamination and associated debris.

Aquafighter is a cure for water in your tank and your fuel system as it removes water as soon as it is in contact in your fuel. By eliminating water, you avoid the need to use of additional chemicals and biocides. These chemical treatments only treat the symptoms caused by the presence of water in your tank, your fuel system and your engine, not the cause. In addition, Aquafighter is completely safe to handle and contains no harmful chemicals. Many after-market additives, chemicals and absorbents may contain substances that are bad for the environment, hazardous to health, and detrimental to the efficiency of engines.

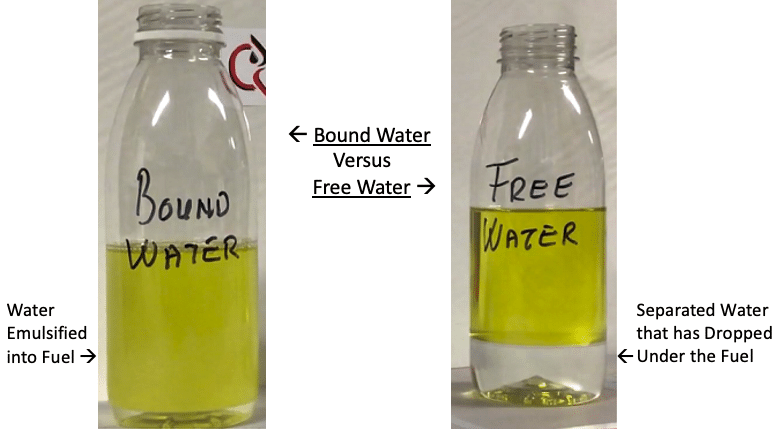

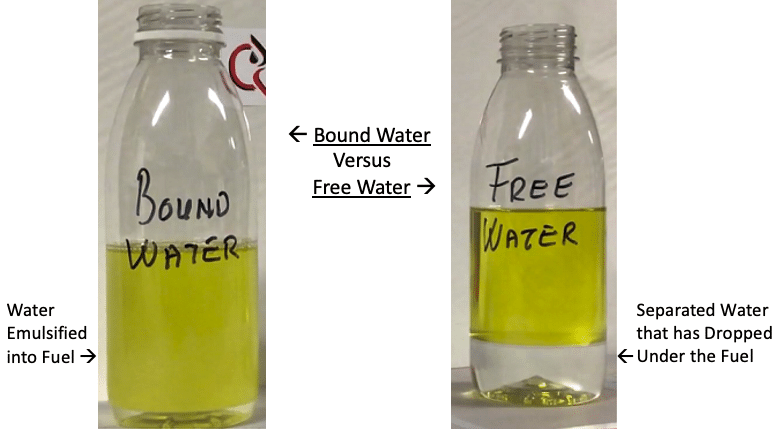

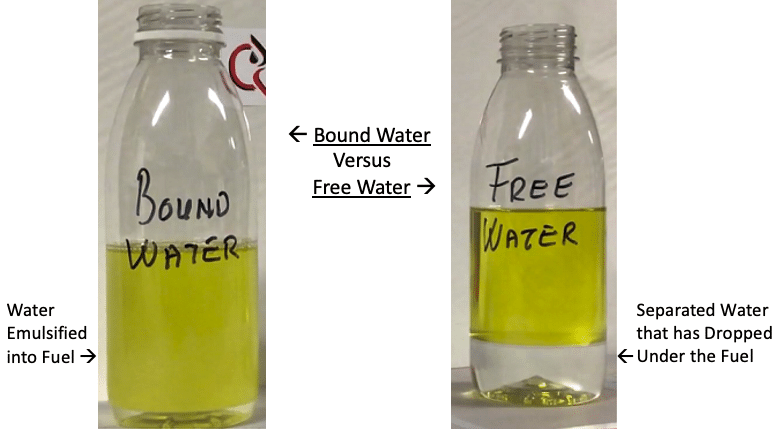

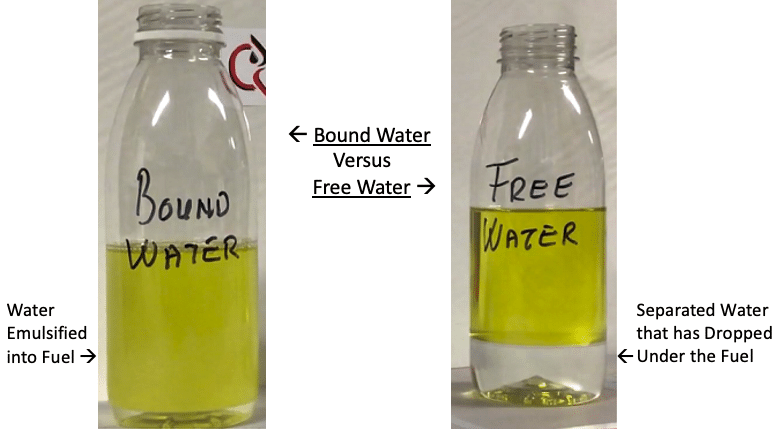

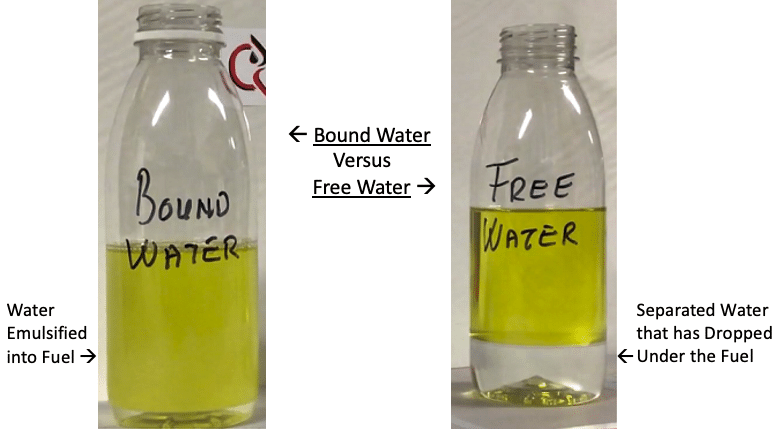

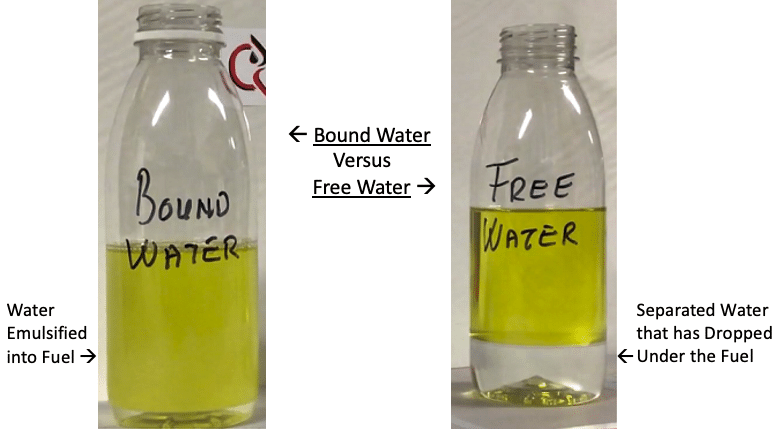

A water separator system is designed to remove and collect undissolved (free) water and solid contaminants, but not to remove readily emulsified (bound) water. In engine systems water-laden emulsified fuel is more likely to drawn into the engine during use. Note that engine OEMs do not typically cover water damage while equipment is in warranty, it is the customer’s responsibility to protect their equipment by providing on-spec fuel to the engine. This is why Aquafighter’s ability to remove emulsified water is so important to protect your equipment.

Aquafighter is not designed to remove free water from tanks, there are much simpler and more effective methods for free water removal. We recommend that you either drain or vacuum out as much free water as possible prior to installation.

Each Aquafighter product has a different maximum water capacity to suit different tank sizes, we have Aquafighters that can capture and remove up to 60 litres of water.

Choose one of the following:

- The best and easiest method is to simply pull up the Aquafighter from the bottom of the tank to visually inspect. Water-saturated Aquafighter powder swells and turns red. Change the Aquafighter when over half-full

- For a non-invasive check you can monitor the downstream water separator, if installed, for the presence of water

- Alternatively, you can insert an Aquafighter Dipstick Indicator through the tank’s dipstick pipe to detect the presence of emulsified water. If the dipstick filter when withdrawn is saturated with water, then the installed Aquafighter filter is likely to have reached its maximum capacity and should be replaced

Under normal circumstances, and with the correct size Aquafighter product, Aquafighter can be kept in a tank for several months up 1 year, depending on Aquafighter model and tank size. However, there are situations such as badly contaminated fuel, high humidity periods or where water ingress/leaks occur that will impact the effective usage time in the tank.

Aquafighter should be disposed of in “special waste”, the same as disposal of used oil filters and other similar fuel contact products.

No. In fact, Aquafighter will restore your fuel to within specification for water content.

No. The Aquafighter fabric membrane is designed to resist expansion. The fabric integrity is maintained so that there is no risk of leaks when removing the product from a tank when it is full. So long as you follow the Aquafighter guidelines for proper access regarding tank entry size, you can leave Aquafighter in your tank for several months and still be able to retrieve it easily through the same entry point. However, once an Aquafighter is fully saturated it will no longer be able to remove more water from the fuel, so ideally a replacement should be installed well before that time.

No. Unless you deliberately cut it or alter it the Aquafighter will not break. The Aquafighter fabric is strong and durable and will keep the gel enclosed safely inside.

Aquafighter is the most affordable solution to keep your diesel tank water-free. In almost all cases, it is the only effective solution to keep your tank free from emulsified water.

Emulsified water is water that is chemically stable in the fuel-phase. Emulsified water does not readily separate itself from diesel fuel and do not readily generate free water at the bottom of fuel tanks. Emulsified water will render the appearance of fuel hazy and cloudy.

Biodiesel blends can contain up to 25 times higher moisture content than regular diesel. By increasing the amount of biodiesel (FAME) content, the greater the overall water content will be observed. Biodiesel can significantly raise the water saturation point of fuel even when a small percentage is added. In summary: More biodiesel content = More emulsified water content.

Emulsified water will over time induce corrosion, it can damage metal parts in fuel systems, it can cause engine performance issues, and will degrade the fuel properties. All water in fuel provides the required conditions for microbial contamination to develop, leading to biomass, filter and injector blockages.

Since emulsified water cannot be simply drained from the tank, there are really only 3 options:

- You can just operate with high water-content fuel with possible adverse effect on your equipment. This offers a real risk to engine performance, tank and component damage

- You can hire a fuel polishing company who will bring a filtration system to re-circulate and clean the fuel. This can be costly process with no guarantee that the fuel water content will be below 200 ppm. Depending on how dirty the fuel is, it may take several days and quantities of filter elements to clean the fuel

- You can maintain an Aquafighter in your tank at all times and never have to worry about excess water in your fuel, this would seem the perfect choice

Absolutely. Water, both emulsified and free, provide the essential conditions for microbial colonies to grow in fuel. Proliferation of bacteria and other hydrocarbon fuel degrading microorganisms is quite common in the presence of excess water in fuel systems. By maintaining an Aquafighter in your tank at all times, you will remove the essential ingredient for the development of microbial contamination.

Test your fuel system periodically with FUELSTAT test kits for instant indication of microbial contamination

By removing and capturing the water in fuel systems, Aquafighter removes the essential ingredient for microorganisms to develop in fuel tanks. This can be confirmed by testing your fuel periodically with FUELSTAT test kits. It gives an instant indication of microbial contamination in your fuel system.

Aquafighter is considered a “Step-1 Solution” because it not only removes excess water, but also prevents water build-up in your tank. As fast as further water is generated into your fuel tank, Aquafighter captures it. Water will be eliminated before it can cause damage to your tank, pump, fuel system or equipment.

Aquafighter has proven itself to be efficient in removing water from both static fuel tanks, and from tanks supplying moving operational equipment while not being used. Aquafighter is also suitable for deployable fuel tanks and fuel bladders used in remote locations where tank maintenance is not always practical and/or done regularly. Aquafighter will remove all water, purifying the diesel fuel to better than specification. Your best option is to install Aquafighter in your tank to give yourself the absolute best fuel protection.

Microbial Contamination (bacteria and Diesel bug):

Microbial contamination is a very serious issue for all users of middle distillate fuels and diesels. A combination of fungi, bacteria & yeasts can feed on the fuel and grow into clumps and films that can cause issues such as; blocked filters, contaminated water scavenge systems, Fuel probe malfunctions & Blocked injectors. See our Microbial Contamination pages to find out more and contact us if you have any queries or concerns about your fuel systems.

Micro-organisms are present wherever sources of food and water exist together. In a fuel system fuel provides the food source, whilst water comes from the fuel itself as well as from external sources like atmospheric humidity, cooling systems and the moisture attractant, (hygroscopic) nature of biofuel.

Water is heavier than fuel and so is found at the bottom of tanks &stores. Microbes tend to live at the water fuel interface, living in the water and feeding off the fuel. They also seek out low flow areas of fuel system and are known to over time to actively create these conditions by ‘digging in’ to structure of tanks and lines, resulting in corrosion and pitting. Heavy contamination can block filters and stop engines too.

Governments worldwide are taking measures to reduce emissions and eke out dwindling fossil fuel stocks. There is also an imperative to reduce the economic risk of and politically unacceptable dependence on fossils fuels and their suppliers. The emissions drive has led to sulphur, seen as the main culprit in the emissions issue, being targeted for reduction. Adding biofuels to fossil fuels is seen as the best current solution to eking out fuel stocks and spreading risk.

Sulphur is a lubricant and so cutting its levels increases fuel system wear and reduces efficiency. Older engines in particular suffer from its reduction. Sulphur also is a bacteria-stat. This means that it interferes with the lifecycle of bugs and slows down their ability to colonise the fuel system.