Backup Power Generation - COVID-19

The reliance for continued and uninterrupted power supply is critical for data centres enabling our on-line working, and hospitals and other municipal facilities. Indeed, in the United Kingdom, global generator organisation, Aggreko, has indicated its willingness to provide the NHS (National Health Service) with up to 1,300 generators to help relieve the strain being put on the medical industry during its time of need.

What often goes unrecognised with these generators is that many run off diesel fuel and as such this precious commodity needs to be protected to ensure that these critical power units can provide the energy on demand, and efficiently, when they are needed most.

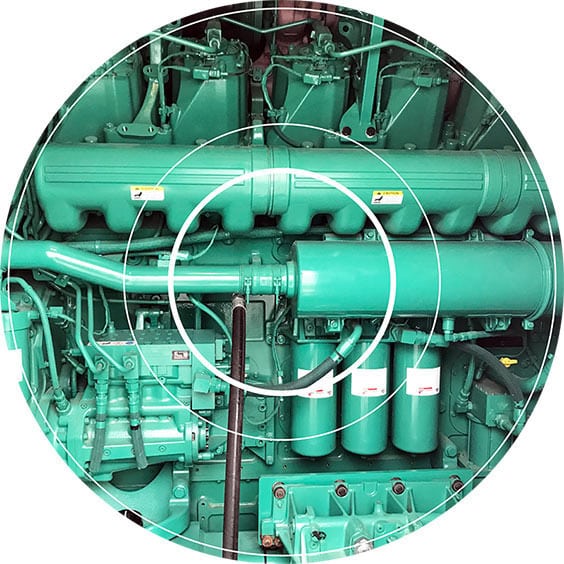

With this in mind, Conidia Bioscience, leaders in fuel microbiology, have some simple steps to follow that will help to protect these vital assets from potential failure owing to fuel related issues, and not through the fault of the equipment itself. When fuel is stored in static situations, condensate within the system creates a water layer within the fuel. Areas where water and fuel are present together provide the perfect growing conditions for microbes such as fungi, yeasts & bacteria, some of which can form a biomass and be extremely problematic, causing blocked filters and injectors, engine inefficiencies and possible failure. To minimise risk, a cost effective, preventative maintenance fuel management strategy should be incorporated for backup power generator systems:

- Test the fuel storage tanks servicing the power units for fuel quality and microbial contamination

- Check and drain water separators (where possible) contained within the power unit. Test any water present in the water separator with a simple pH test kit. Samples that are acidic in nature indicate that something is not right with the fuel supplying the power unit

- Check filters (where possible) for signs of sludge, black spots and any other foreign matter. This is often a result of microbial contamination in the fuel system

- It is always prudent to test incoming fuel supplies to ensure that you are not importing contamination issues, especially during these critical times

- Test as quickly as possible, preferably on-site and at the tank for signs of water, microbial contamination (bugs) and particulate. Where there are signs of microbial contamination it is important to treat this at the earliest opportunity, as like a virus this can be transferred from asset to asset, or storage tank to power unit

- Fuel polishing units can assist in ensuring that the fuel supplying generators is filtered, cleaned and/or rotated regularly to help minimise the risk of fuel related issues

- Test again at regular intervals to ensure that risk has been minimised

Let’s not allow problems associated with static fuel to hinder the good work being conducted globally to beat COVID-19, and instead continue the joint efforts of global governments, health care workers, corporations and the world’s communities to work together as one to get through this.

Please visit the following pages for more information of microbial contamination, its effects and how to minimise the risk:

If you have any questions on this, or any subject regarding microbial fuel testing, please contact us on info@conidia.com, or via live chat on the website.