Jet Fuel contamination and how to detect it

In fact, one instance of jet fuel contamination caused a large commercial aircraft to be grounded for over two weeks.

This grounding was a consequence of microbial contamination, and had a huge financial impact through both treatment of the contamination and lost revenue.

Also, with the growing economies in China, India, Brazil etc. and the resulting demand for aviation, more flights are now conducted in high-risk zones. As a result, it’s more important than ever to detect contamination early.

Read More >> Aviation Fuel Testing

What are the main causes of Jet Fuel contamination?

Despite the protective coatings on the interior surfaces of fuel tanks and pipes, they contribute particulates like rust and scale to fuel. Even small quantities of water in jet fuel distribution systems will lead to rust developing and eventually entering the fuel.

In addition, airborne particles like dust and pollen, rubber and fabric particles, and solids from microbial infestation (like cellular debris and microbial by-products) find their way into fuel.

The accumulation of water is almost inevitable in stored aviation jet fuels and in operations. Even if the fuel has low water content when delivered at the airport, there are multiple opportunities for moisture to be taken up.

Moisture can come from free water gathered in low spots in a pipeline, rainwater leaking past the seals in floating-roof tanks, and moist outside air entering the vents of tanks. Air flowing in and out of a tank when fuel is added or removed may also change the moisture content of the air in contact with fuel.

If aviation fuel is contaminated with another petroleum product to the extent that the fuel’s specification requirements are no longer met, then there is no remedy. The fuel must be returned to a refinery for reprocessing.

One contaminant that has been encountered in airport supply systems in recent years is Fatty Acid Methyl Ester (FAME). This material is most likely to be found when biodiesel fuel has passed through a common unsegregated fuel distribution system.

Although aviation fuels are sterile when first produced, they inevitably become contaminated with microorganisms that are omnipresent in both air and water. Microorganisms found in aviation jet fuels include bacteria, yeasts and fungi.

When these microorganisms grow, they form solid debris that effectively plugs fuel filters. Some microorganisms also produce acidic by-products that can accelerate metal corrosion. Since most microorganisms need free water to grow, microbial growth is most commonly found in any place where fuel meets water.

How do I detect contaminated jet fuel?

Particulates like rust, scale, dust and pollen are determined by visual inspection of the fuel sample. Chemical analysis can also be employed to detect particulates beyond visual inspection levels.

Water in aviation jet fuel can be detected in several different ways. The most common method is known as a water tablet test for fuel. This very briefly indicates whether the water in fuel is above or below 30 ppm, the maximum allowed limit.

There are many other products and analysis equipment commercially available that can test for jet fuel water contamination.

Microbial contamination in jet fuels is typically detected through CFU tests, ATP tests, or Immunoassay antibody tests. The CFU method usually requires sending fuel off-site for testing, which can take up to 10 days. ATP gives results in minutes but requires to be done in a laboratory with special equipment so is not generally classed as on-site.

Immunoassay antibody tests are done on-site, on the spot, and requires little training and no special equipment. Results come in 10-15 minutes in an easy to interpret format.

FUELSTAT® 15-minute immunoassay antibody test

Test for all known microbes that are dangerous to fuel in minutes.

Which type of contamination is most dangerous?

But in general, microbial contamination is the most troublesome. The danger posed depends on the type of organism, the jet fuel itself, and any additives used.

Whilst a wide range of potentially dangerous microorganisms is found in aircraft tanks, one of the most serious is the filamentous fungus, Hormoconis resinae (H.res). It is present in many cases of contamination found in aviation jet fuel, according to IATA (International Air Transport Association) who classify H.res as the predominant fungus found in jet fuel. The other cases are made up of bacteria and other fungi, including some yeasts.

H.res is damaging in fuel because of several reasons:

- Size and bulk. When compared to yeasts and bacteria, H.res produces far more biomass and is thus more likely to cause blockage problems.

- Corrosive effects. The by-products of microbial metabolism from H.Res, along with other microorganisms, can induce harmful corrosion in aircraft fuel tanks (see Aircraft Fuel Testing).

- Staying power because of the way H.res grows between fuel and water. It usually starts on small water droplets, then covers the droplet, holding it in place. It then continues its growth, generating more water due to its metabolism. In the process, it firmly attaches itself to the tank, staying even after the water is drained.

What happens if microbial contamination is left to grow unchecked?

Microbial contamination, including H.res, can be extremely damaging to engines, fuel gauges and other aviation equipment. It is also highly corrosive to fuel tanks and systems, potentially resulting in dangerous and costly fuel links.

This kind of jet fuel contamination, left untreated, can be extremely costly to your business for three reasons:

Fuel treatment costs

In order for the fuel to be made usable again, it will usually be treated with biocide. This alone can cost thousands.

Engine and equipment repair costs

Microbial contamination, and the biomass it creates, can cause engines, gauges and filters to malfunction and require repair.

Lost revenue

Contaminated assets often need to be taken out of operation temporarily. In the case of aeroplanes, this can cost the owners hundreds of thousands of dollars, or even millions.

If you’re a user or distributor of fuel, you cannot afford to let severe contamination problems develop. It’s far more cost-effective to simply test your fuel as part of a proactive fuel maintenance program.

FUELSTAT® 15-minute immunoassay antibody test

Test for all known microbes that are dangerous to fuel in minutes.

Which tests can identify jet fuel contamination?

CFU Growth Tests

This is a ‘catch-all’ testing method that finds any culturable microbes present in fuel (even ones that aren’t dangerous to fuel at that point). Fuel samples must be sent to a sterile off-site laboratory for testing, so getting results can take up to 10 days. There is a commonly used CFU growth method using a thixotropic gel that can be done on-site but still requires incubation on-site or at a testing location.

ATP (Adenosine Triphosphate) testing

This is also a ‘catch-all’ testing method. It can be conducted on-site but requires expensive equipment and highly-trained testing personnel.

Immunoassay antibody testing

This method finds only specific microbes that are dangerous to fuel. It delivers results in minutes and can be carried out on-site with minimal training.

01.

Are there any drawbacks to sending fuel off-site for CFU Growth testing?

This requires sending them under ice to a laboratory or testing facility, with the journey taking no more than 24 hours. The fuel sample is then tested using the CFU growth method called IP385.

However, sending fuel this way is both difficult and troublesome. Even under ice, fuel can undergo significant temperature changes, for example, if ice melts or the packaging is faulty. The microbes present can grow rapidly in warm temperatures, ‘go to sleep’ in colder temperatures or dry conditions and even finish their short life cycle during transit. So, transporting samples off-site can potentially reduce the accuracy of CFU tests.

02.

What does IP385 CFU Growth Test actually test for?

It will look for culturable microorganisms that are able to grow in the test environment. Consequently, the results make it difficult to see which species of microorganisms have appeared, and whether they are likely to cause issues in jet fuel systems.

Because of their ‘catch-all’ nature, results from IP385 tests may bring up a false alert for jet fuel contamination. Without further laboratory work to establish which species of microbes are present, there is little way of accurately understanding what the findings mean.

03.

How IP385 CFU testing can lead to unnecessary fuel treatments

The numbers are then often assessed against IATA industry guidelines for jet fuel contamination by the laboratory operative.

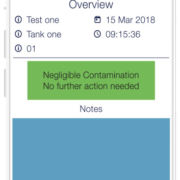

The number of dots (colonies) counted result in a verdict of negligible, moderate or heavy jet fuel contamination. The next recommendation if there is moderate contamination or above is to treat the fuel with biocide—but, the risk is, such treatment may not actually be required. The microbes counted may not be harmful to fuel at that point, so the contamination verdict could be misleading.

Biocide treatments incur expensive product and labour costs, and fuel owners have to make additional technical and safety considerations. Biocide needs ultra-strict handling and usage, and must not be used so often that would allow development of microbial resistance over time.

04.

Is ATP an effective testing method?

It requires fuel to be sent to an appropriately equipped testing facility and gives an almost instant result for jet fuel contamination.

ATP testing is done with an expensive piece of laboratory machinery, known as a luminometer. However, the high cost of a luminometer means ATP testing may not be financially justifiable for operators, repair companies, or fuel suppliers with lesser testing needs.

To ensure that jet fuel tests are accurate, ATP also requires testing personnel with generally some scientific experience. Results are matched against parameters set out by bodies such as IATA, or by fuel manufacturers, to determine levels of jet fuel contamination.

As with IP385, ATP is a ‘catch-all’ aviation jet fuel test. It doesn’t identify what specific microorganisms have been found, and instead simply records the amount of ATP produced by living cells in the sample, which is assessed against a scale—again, this means misleading test results are possible.

05.

Immunoassay antibody tests: on-site testing designed to prevent false alerts

They rapidly identify jet fuel contamination, giving results in 10-15 minutes, with zero additional laboratory equipment needed.

Immunoassay antibody jet fuel tests are easy and can be learned in minutes by people with no prior scientific or laboratory experience. The testing is unique because it only looks for specific microbes that cause issues in aviation jet fuel systems. That means a much lower possibility of misleading results caused by unknown species of microorganisms being counted.

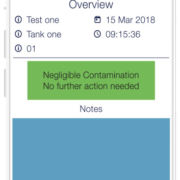

Results are specific and easy to understand, requiring little analysis or input from the user of the test. They indicate which microorganism species types are present, be it bacteria, other fungi, or the specific H. res fungus. They show what level of microbial contamination is present, within set ranges, without the need for further calculation or cross-checking.

Read More >> Fuelstat – Fuel Testing Kit

See how FUELSTAT® can save you time and money

by testing for jet fuel contamination early

FUELSTAT®: The Easy and Rapid Test for Detecting Microbial Contamination in Jet Fuel

It can be utilised anywhere aviation jet fuel is manufactured, put in storage, distributed, or used in an aviation setting.

The test kits only look for microorganisms known to do damage to fuel and the fuel systems supplying aviation. It’s the only test that can deliver accurate results in as little as 10-15 minutes, compared with four days for traditional methods such as CFU testing.

Unlike other tests, FUELSTAT® provides fast, under-wing testing, just minutes after the fuel is taken from the tank. You get an accurate and up-to-date assessment of microbial contamination in the fuel tank itself.

Test for jet fuel contamination in 3 easy steps

Step 1

Test with FUELSTAT®

Step 2

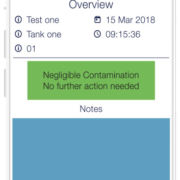

Scan the kit with the FUELSTAT® Result app on your smartphone

Step 3

See full Analysis Report from the app on FUELSTAT ® Result Portal, with all results stored for later retrieval and analysis

FUELSTAT® is sold in over 130 countries globally and used regularly by over 400 airlines. It is compliant with International Standard ASTM D8070.