How to manage the risks of diesel fuel contamination

Microbial contamination, in particular, is almost always present in fuels to some degree. Left unchecked for too long, it can do serious harm to engines and tanks, and even cause leaks and environmental damage.

Read on to learn more about diesel fuel contamination and diesel fuel contamination tests.

What is microbial fuel contamination?

With numerous applications in both industry and transport, diesel fuel also has a large storage and supply network that helps to maintain supplies globally.

Diesel fuels can be prone to diesel fuel contamination — a form of microbial contamination that’s also known as diesel bug or diesel fungus.

Microbes are naturally all around us and are capable of adapting to survive in harsh environments. They include bacteria, yeasts, and fungi that can thrive in fuels, feeding off water and hydrocarbons in the fuel. These microbes can do serious damage to both fuel systems and the supply infrastructure for diesel fuels.

How does microbial fuel contamination occur?

Because they are ever-present, it’s easy for them to enter fuel during transport and storage. Microorganisms that thrive and do damage to fuel systems are generally aerobic, meaning that they require oxygen, which they can get from water, to survive and thrive. They get nourishment from the hydrocarbons in the fuel.

Water enters fuel in several ways, but mainly through condensation that occurs when the temperature in and around water changes. Microbes are microscopic, i.e. so small that they cannot be seen by the human eye. That means that even the smallest amount of water, a single droplet, is enough to help microbiological diesel fuel contamination occur and persist.

These microorganisms can develop in fuel systems, and hotter conditions can lead them to grow faster. When you factor in humidity as well, the risks of diesel fuel contamination get higher in regions closer to the equator.

Companies that use or supply diesel fuel need to manage the risks of diesel bug on an on-going basis. In addition, recent changes to diesel fuel make this task even more important today.

FREE White Paper:

Find out how Aquafighter® water removal filters and FUELSTAT® test kits can be part of the solution for a cost efficient fuel management programme.

FUELSTAT® diesel testing kits

Test your fuel for microbial contamination on-site in just 15 minutes

Environmental changes affecting diesel fuel contamination

These changes have been introduced in order to help the environment. There are indications suggesting that they increase the risk of diesel fuel contamination developing in your asset—whether it’s a generator (see Diesel Generator Fuel Testing), ship engine, storage tank or something else. The changes to diesel fuel are:

The introduction of increased levels of biodiesel

which is known as FAME (Fatty Acids Methyl Esters) biodiesel. FAME biodiesel is designed to be kind to the environment but can increase the growth of dangerous microorganisms. This is because biodiesel absorbs significantly more water from the atmosphere, which adds to the risk of diesel fuel contamination.

The reduction of sulphur

in diesel fuels is also possibly a factor in diesel fuel contamination risks increasing. This reduction has occurred as a result of ultra-low sulphur diesel being introduced in transport and marine operations. Major legislation, for example, International Maritime Organisation 2020, means many companies need to follow specific guidelines on sulphur reduction.

Read More >> Marine Fuel Testing

How will these changes affect engines and fuel systems?

Scientists generally conclude that the introduction of biodiesel (FAME) is likely to result in higher levels of diesel fuel operational issues. This finding was detailed in the study “FAME Blended Diesel Fuel Impacts on Engine/Vehicle Systems” by Kono, Yamamori, Furukawa and Noorman (2011).

The exact effects of reduced sulphur in diesel on the growth of microbial contamination are not yet fully established. At the time of writing, there are differing opinions within the scientific community.

Regardless of the current scientific research, there are strong reasons to pay attention to fuel management issues. Lower sulphur diesel costs more to produce, and these costs are passed on to the supply chain and user. As a result, diesel maintenance is an important cost-reducing activity: it costs far less to maintain fuel than to replace it.

Another consideration for users is recent diesel engine legislation, such as Euro 6 in the EU. This legislation means that fuel manufacturers have to meet even more stringent requirements for emission controls. Accordingly, diesel fuel contamination can increase the risk of engine problems and potential engine failure in newer, more sophisticated engine designs. This is because some of the more sophisticated engines have far smaller tolerances for contamination.

FREE White Paper:

Increases in bio-content in fuels have the potential to increase Microbial Growth (MBG) in fuel systems. This paper discusses the reasons why and equipment protection via fuel testing.

What does a build-up of diesel bug in contaminated diesel look like?

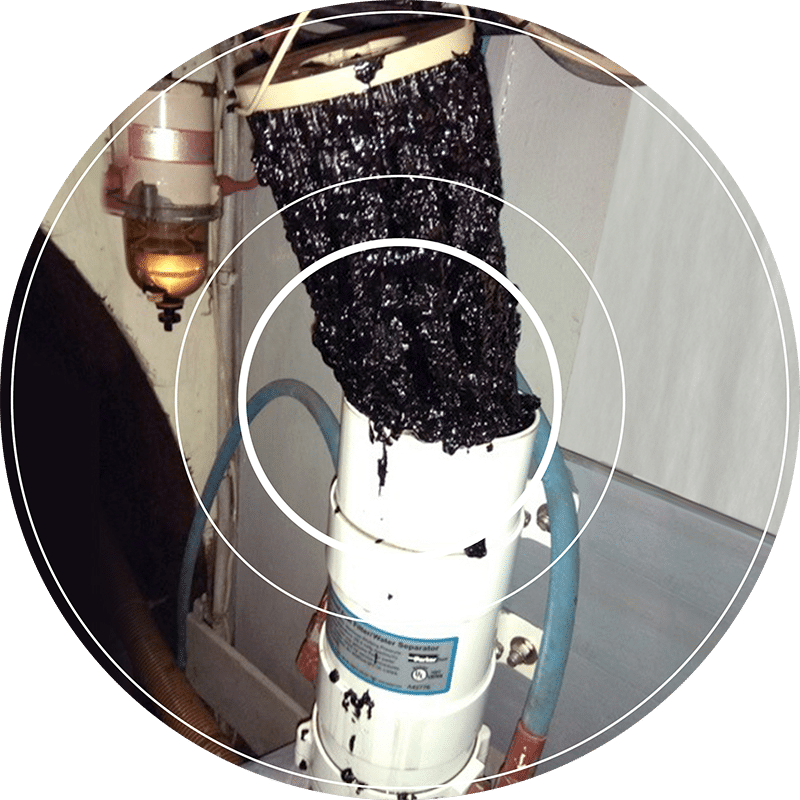

For example, it may manifest in the form of something called biofilm, which appears as a shiny film layer. Biofilm builds up as some species of microorganisms live off the by-products that other species create. The microbial cells will stick to each other, and to nearby surfaces, becoming embedded in a slimy extracellular matrix that is composed of extracellular polymeric substances (EPS) and is produced by the microbial cells.

Diesel fuel contamination also forms biomass (accumulation of microbial cells), which may look like a thick, slimy material. Biomass can be present even when you are unable to see it. Biomass can obstruct engine mechanisms so that the engine works less effectively—or even stops working.

One of the most well-known species of microorganisms that thrive and does damage in fuels is a fungus called Hormonconis resinae. Abbreviated as H.res, this fungus produces bulky biomass and is thus more likely to cause blockage problems.

Diesel fuel contamination can also create dangerous acids, which can destroy plastic, rubber and metal parts of fuel systems and tanks.

What contaminated diesel fuel symptoms should you look for?

Incorrect fuel level readings

Biofilm can coat fuel quantity systems in tanks, such as the probes that measure fuel levels, so they don’t work properly.

Poor engine performance, or total failure

When filters get blocked, they cause poorer engine performance with decreased economy and higher emissions. If the engine is completely starved of fuel as a result of a blocked fuel filter, it may stop working completely.

Injector malfunction

Injectors are fitted to more sophisticated systems and are more likely to malfunction when clogged up by injectors.

Reduced reliability and life of asset

The acids formed by diesel fuel contamination, along with their corrosive effects, have significant impact on assets using said fuel.

Leaking tanks

Fuel contaminated heavily by diesel bug can develop corrosive acids that cause tanks to leak.

In very tough and competitive global markets, you cannot afford to have assets not working at maximum efficiency. And where your asset is part of a safety-critical process, it is vitally important that all risks are managed as far as is reasonably practicable.

Organisations that store diesel fuel also have a responsibility to protect this precious commodity itself. The priority is not only to guard the value of the fuel but also to prevent fuel from leaking into the ground and causing serious damage to the environment.

Serious safety or environmental issues often make the news—even national news, if the scale of impact on life or pollution is large enough. This kind of PR disaster, plus the consequences that come with the intense scrutiny afterwards, can seriously affect an organisation’s reputation.

FUELSTAT® Diesel Plus – FMD8 - testing kits

Test your fuel for microbial contamination on-site in just 15 minutes

How do you manage the risks of diesel fuel contamination?

Basic fuel maintenance, in comparison, costs relatively little—so it makes good business sense to do these activities.

To minimise the risks, there are three key activities you need to do:

It’s virtually impossible to stop water from entering fuel. In fact, water can enter fuel at any time in the supply chain once the fuel has left the refinery. It’s therefore important to regularly remove any water present in fuel.

Many users and distributors of fuel manually check for something called water bottoms—a layer of water that builds up under the fuel. Water bottoms occur when water (being heavier than fuel) sinks to the end of a storage tank. This water is most commonly removed by opening a valve at the lowest point of the tank.

A tank should never go more than six months without having its water bottom removed. However, to help prevent diesel fuel contamination/diesel bug, water draining is recommended as often as is possible, daily if necessary. This is especially recommended in summer, or in regions with 20+ degrees Celsius average temperatures.

Where and how diesel fuel is stored is important in any fuel maintenance programme. It’s important that tanks and vessels are protected against rainwater or any source of water that may enter the tank via loose filler caps, worn seals, torn gaskets, broken tank breather pipes, etc.

Some users and owner of tanks containing diesel fuel opt for automatic tank gauging systems (ATG). These systems use sensors that automatically detect the presence of water and alert the operator.

It is also important to check for diesel fuel contamination regularly using a diesel fuel contamination test. These tests are conducted either by sending a sample to a laboratory or conducting a test on-site where the tank or engine is kept.

Read More >> Fuel Test // Diesel Fuel Contamination Test Kit // Diesel Bug // Fuel Testing Kits // Aviation Fuel Testing // Jet Fuel Contamination

What are the best tests for diesel fuel contamination?

01.

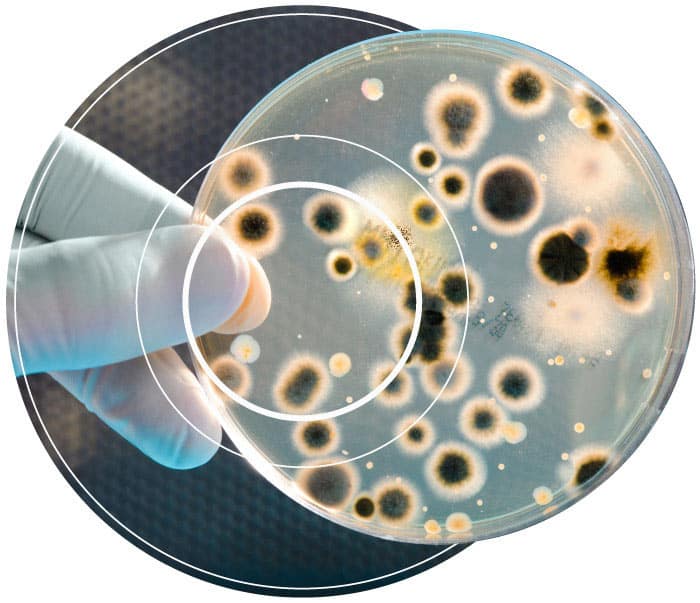

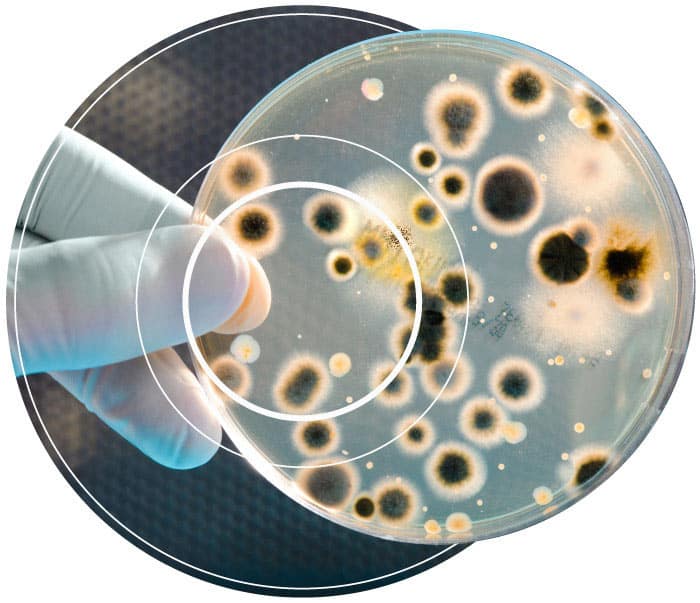

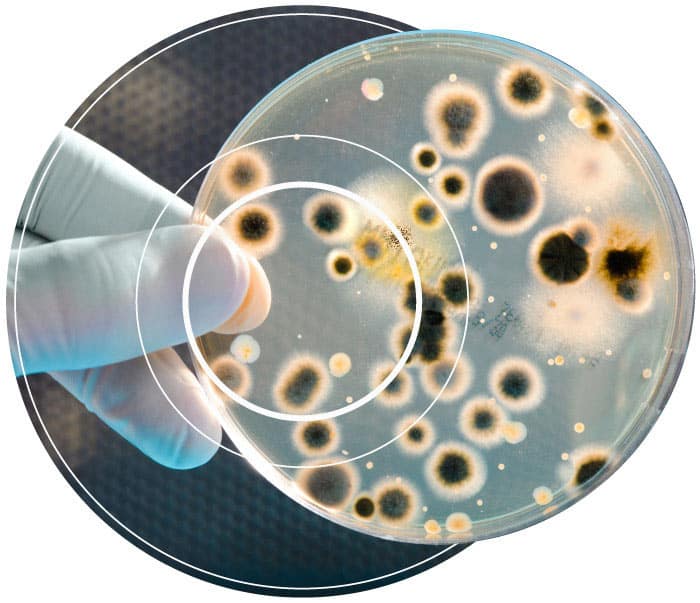

Colony Forming Unit (CFU)

CFU tests try to establish the level of microbial presence in a fuel sample. To achieve this, they use an incubator to grow and count culturable microbes present in the sample (not just the ones that do damage to fuel systems).

Laboratories with fuel testing capabilities may not always be in close proximity to where the sample was taken, so there are handling and transport issues to consider, along with transport costs. If fuel is being transported off-site, it must be tested for diesel fuel contamination within 24 hours. This requirement can be very challenging to comply with, especially when the fuel sample is taken from a ship or offshore.

Overall, CFU testing is a difficult process and can be costly when handling, transport and actual laboratory costs are factored in.

There are cheaper, simpler tests available, but they are largely obsolete as they have not proven to give reliable results for a variety of reasons. In addition, they will only test in the water phase of fuel, so if no water is present then the test cannot be completed.

03.

Immunoassay antibody tests

It works using an ‘add drops and wait’ system that is reminiscent of human pregnancy tests. Unlike CFU testing, the method is very fast, and only looks for microbes that cause harm to diesel fuel.

When using immunoassay antibody tests, there is no need for complicated equipment, sterile laboratory conditions, or scientific training. The user simply needs a flat surface and a clean sampling bottle and can conduct the test wherever the fuel is being stored. Immunoassay antibody tests generally give results within 10-15 minutes.

02.

ATP testing

However, it requires an expensive piece of equipment called a luminometer in order to conduct a test. The diesel fuel tester also requires a certain amount of training and experience to achieve reliable results.

Similar to CFU, ATP testing looks for total microbiological presence, not just the microbes that do damage in fuel systems. Because of this broad testing scope, misleading results are possible.

ATP testing is usually conducted at a different location to where the fuel is being stored or used. There is a risk of exogenous microorganisms or other living cells entering the sample during the sampling, handling or transport phases. This can lead to misleading results, where the obtained signal from living cells is not directly reflecting the actual number of microbes present in the tanks.

FUELSTAT® Diesel Plus – FMD8

Immunoassay antibody diesel testing that gives results in 15 minutes, right at the tank

FUELSTAT® Diesel Fuel test

Easy to use

No scientific training is required, and you don’t even need sterile testing conditions.

Specifically designed for diesel fuel contamination testing

The tests only look for microbes that are dangerous to fuel and ignore the rest.

No special equipment needed

Each FUELSTAT® test kit provides almost everything you need; you only have to supply a clean sampling bottle.

Digitally verified results

The test results can be scanned and stored using a free smartphone app, so it’s easy to check your records later.

Learn more about FUELSTAT®

Visit our site now to learn about how FUELSTAT® can help protect your business by catching diesel fuel contamination early